Material Processing and Manufacturing Automation Research Group

Mission & Role

The Material Processing and Manufacturing Automation Research Group focuses on the research and development of production systems based on the knowledge of materials science production process and automation, as well as the engineering design and manufacturing engineering related to material technology. Our goal is to develop suitable technologies that will be beneficial for the industrial sector of the country by applying knowledge and understanding from scientific research for valuable use in terms of hardware development, such as tools and other equipment systems, software development, and highly effective work processes.

Research group’s technology

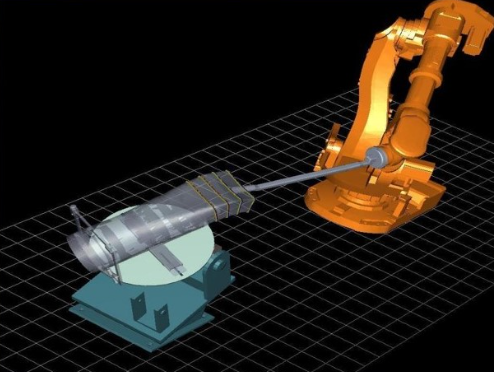

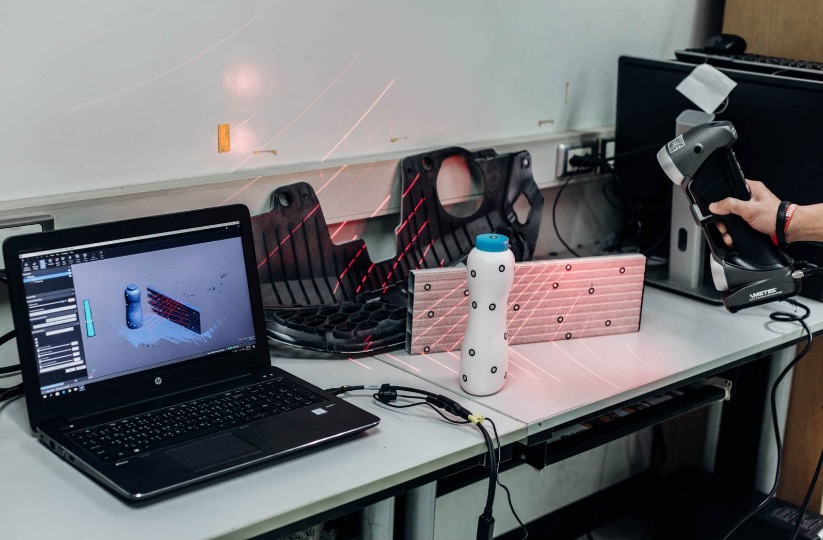

● Manufacturing Automation Systems, such as utilizing robotic system in automated coating process, automated welding repair for parts Power Industry, and Wire-based Additive Manufacturing (WAAM) suitable for building large metal parts.

● Agricultural Machinery and Harvesting Automation.

● Titanium Foaming Technology with the MIM (Metal Injection Molding) and Electroplating

● Aluminium Casting technology and Smart Manufacturing

● Metal forming technology for powder metallurgy parts

● Plastic mold design technology and plastic parts injection molding process

● Metal Injection Moulding (MIM) and sinter-based metal Additive Manufacturing

● Surface Enhancement Laboratory, focusing on chemical surface treatment by electroplating and mechanical surface treatment by fine particle shot peening

Research Teams in Material Processing and Manufacturing Automation Research Group