Automation for Material Processing Research Team

The Automation for Material Processing Research Team has 2 main research activities as follows.

1. Developing the industrial automation solutions for production processes that links to material processes, the automatic control and monitoring of the production process and other automation solutions. The laboratory’s stability is the development of integrated automation with process control based on the understanding of manufacturing processes and materials science.

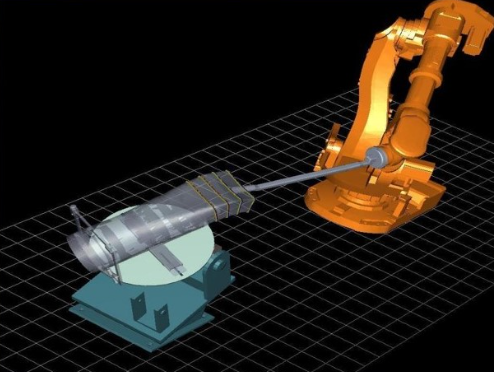

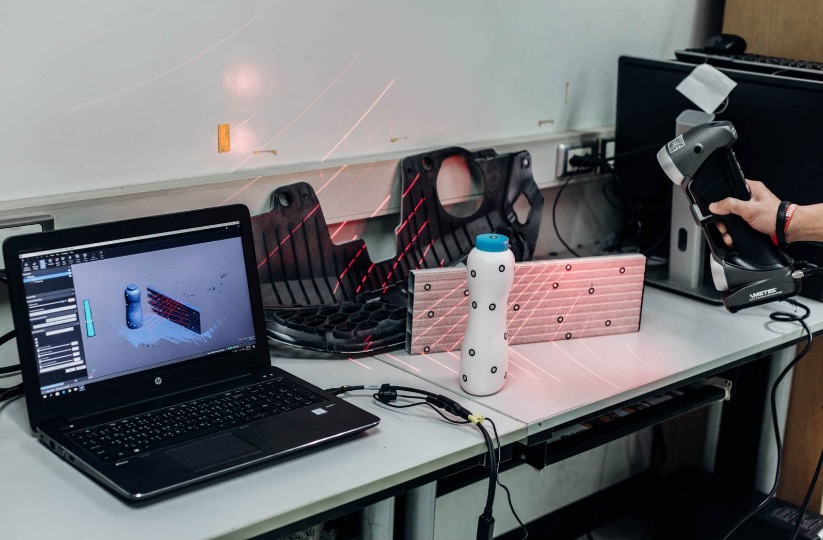

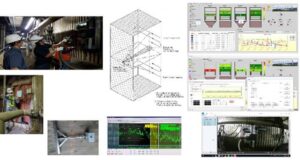

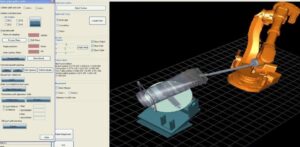

The laboratory’s expertise includes the development of automatic coating software systems with robots, the development of automated TIG and Plasma welding systems with robots and with a moving axis, which designed for specific tasks, the application of Machine Vision in welding processes and automated validation and fault detection, as well as the use of thermal imaging for non-contact automatic damage detection.

Example of works:

|  |  |

| Hardfacing process | Hardfacing process in the valve | Robot scanning for the internal surface of the work piece |

|  |  |

| An automated system in power plants | Machine vision inspection system for pipe fittings | Wall welding with titanium materials |

1. The software development for automatic robotic plasma coating process. For spraying coating with heat of gas turbine engine parts for the Electricity Generating Authority of Thailand

2. The development of an automatic hardening welding robot system for welding and repairing parts of the power plant for the Electricity Generating Authority of Thailand.

3. The development of an automatic camera inspection system for a subsidiary of Siam Cement Public Company Limited.

4. The development of a system related to the automation system in the power plant for the Electricity Generating Authority of Thailand.

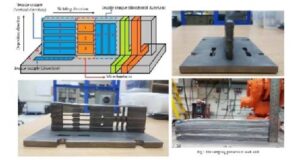

5. Wire-based Additive manufacturing.

|  |

| Working with partnership | Automatic coating software systems with robots |

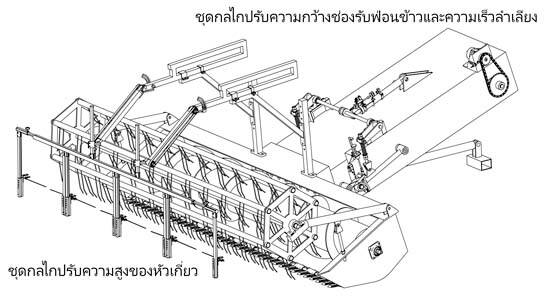

2. Developing an automation for agricultural machinery works by focusing on applying technology to assist in decision making on behalf of operators from the application of the sensors in combination with the control system and designed a set of mechanisms to integrate with the automation to reduce the operators’ errors and solve the problem of labor shortages that require skill and expertise.

Research samples:

1. The development of an automatic height adjustment set of the combine harvester according to the height of the rice plant with Lidra technology and a detection mechanism set, and the development of a set of mechanisms for automatically adjusting the sheave width and conveying speed of the combine harvester for the combine harvester to have a fall harvesting function, a height adjustment set of the combine harvester according to the height of the rice plant, and a management systems for conveying sheaves according to rice plant conditions, etc.

2. The development of suspension and transmission systems of combine harvesters with electric control gear room to reduce the number of pumps and hydraulic motors that is easy to control with 1 lever, as well as help lower the maintenance costs.

|  |

| Height adjustment mechanism for the hook | Power transmission system in the electronic gear room |

The Automation for Material Processing Research Team

Mr. Jiradech Nakngoenthong

Tel. 66 2564 6500 ext. 4153

Email: jiradecn@mtec.or.th

Research Teams in Material Processing and Manufacturing Automation Research Group