Research Background

A synthetic lightweight aggregate “G-Rock” is a research result developed by MTEC. The research team has developed the formulation and production process by utilizing waste materials from various industrial sources within the country. The selection of raw materials is primarily based on their chemical composition and then appropriate ceramic production processes are applied, i.e., a forming process and a high-temperature sintering process to produce lightweight granular materials with good thermal insulation and durability.

At present, the research team has further developed “G-Rock” by applying them in the construction works to solve the heat build-up problems within the building, as well as the problems of the weight of the building parts and the cost of transportation and installation, such as precast concrete walls and floors. The application of “G-Rock” will help improve the properties of lightweight concretes for better thermal insulation and reduce their weight by more than 20%. However, their strength is comparable to conventional concretes.

Research objectives

The research team plans to make use of waste materials from the domestic industries by developing a prototype of synthetic lightweight aggregate “G-Rock” at the industrial level. This aggregate can be mixed with concretes to improve their properties by reducing its weight and construction costs, as well as improving its insulation properties. It can also be applied in various applications concrete forming applications.

What does the research team do?

The research team has cooperated with a private company to design and develop the formulation for the industrial production processes by using by-products from various manufacturing industries, such as ashes from the combustion of biomass fuels and sludge from wastewater treatment.

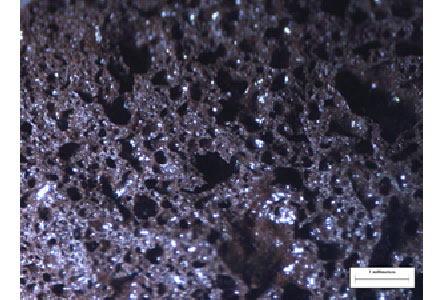

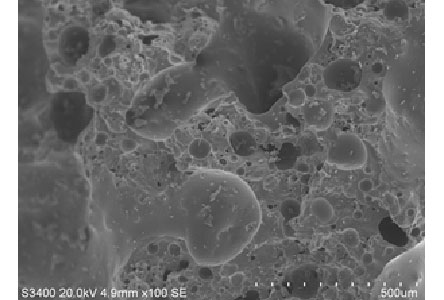

An OM image is at 10x magnification and an SEM image is at 100x magnification.

Research highlights

Synthetic lightweight aggregates “G-Rock” have the following characteristics.

- They have low density, thus making the overall weight of mixed concretes with synthesis lightweight aggregates have reduced to 20-30 %. However, its strength is comparable to most conventional concretes.

- They have good thermal and cold insulation, and good absorption.

- They can be further developed for various applications, such as concrete blocks, concrete roof tiles, precast walls, and pre-tensioned floors.

- They can be used as a replacement for crushed stone or sand, which help reduce the destruction of natural materials.

G-Rock Characteristics

- Lightweight

- Thermal and cold insulation

- High absorption

- High durability

- Low-priced

Research status

This technology has been applied in the commercial production by Charunbusiness 52 Company Limited, a subsidiary company of the Thai Beverage Group, under the trademark name “Green-Rock”.

Outlook

The research team plans to cooperate with PCM Construction Materials Co., Ltd., which is the leading manufacturer of precast concrete wall panels in Thailand, on the assessment of the heat resistance performance of “Green-Rock” conforming to the project testing of “Green-rock” lightweight concrete wall compared to the conventional concrete walls in the field test. The research team also plans to cooperate with concrete product manufacturers for other applications.

Research team

Dr. Pitak Laoratanakul and Mr. Suteerapun Punlert

Contact

Dr. Pitak Laoratanakul (Principal Researcher)

Ceramic Engineering Research Team

Ceramics and Construction Materials Research Group

Tel. +66 2564 6500 ext. 4242

Email: pitakl@mtec.or.th