An ambulance is developed and used to transfer patients to a nearest nursing home or a hospital. During the transfer, the trained ambulance personnel can provide the basic health-care treatment by using emergency medical facilities and equipment present inside an ambulance. The ambulance compartment, mostly in Thailand, is built and converted from commercial van by local manufacturers. There are several constraints in the lack of safety design of the compartment, for example, low technology in design, a limit of production cost and an unclear national policy on road safety which result in road accidents, especially, a rollover accident. The injuries in the case of rollover are mainly related to the degree of roof crush and impact of the occupants on the interior (e.g. roof or pillars) of the vehicle.

A solution to reduce occupant injury is to maintain an intact survival space by reducing roof crush of vehicles coupled with effective seatbelt restraint according to requirements adopted by UN R66 (the Economic Commission for Europe of the UN (UN/ECE) in its Regulations: No.66). UN R66 is applied as a guideline to enhance passenger safety for large passenger vehicles regarding the strength of their superstructure by establishing the requirements for passenger survival space (residual space) in case of rollover accident. Here, the approval of a new structurally-improved ambulance is carried out through numerical simulations with validated CAE methodology and physical tests on a prototype according to UN R66. The present works to achieve the safety-enhanced design of the ambulance are proceeded as follows:

1) Studied the technical restrictions for the design of ambulance van and found guidance to do the physical tests and the numerical simulations that can be used for rollover performance approval from the original design of the van.

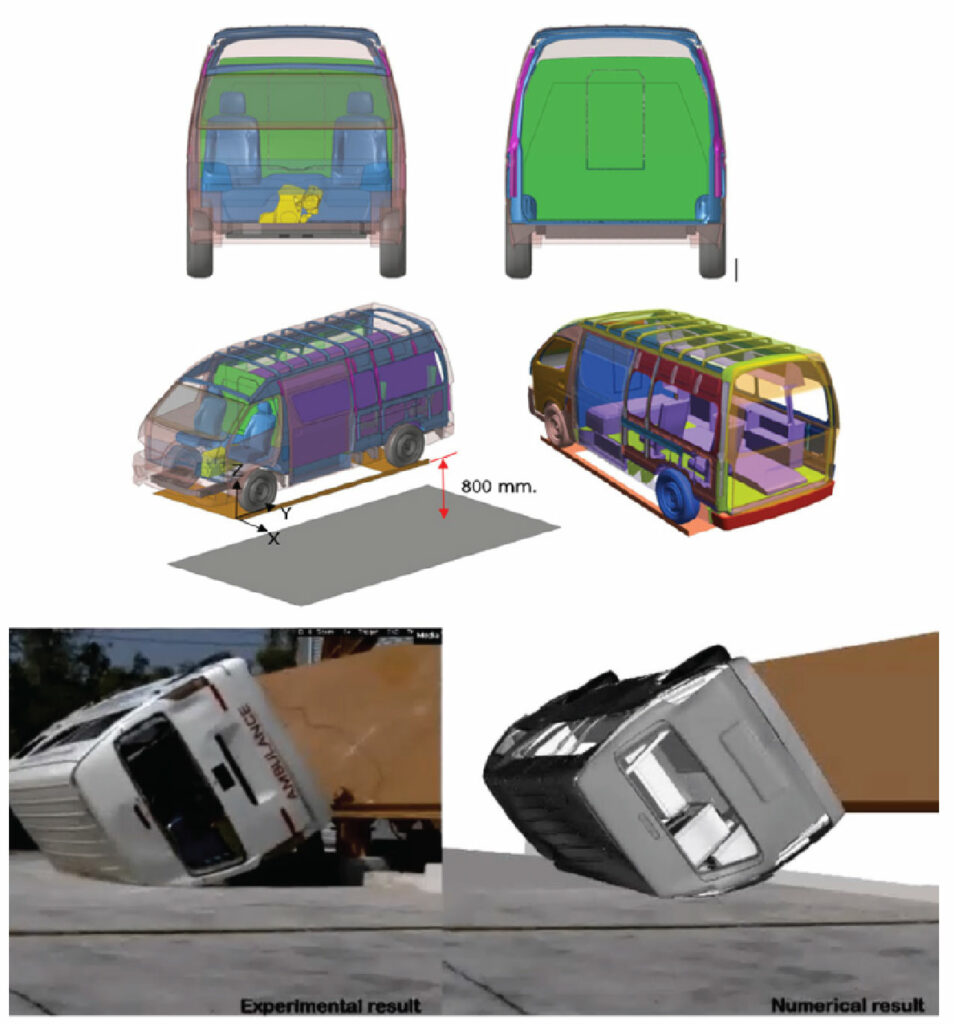

2) Adopted the second-hand van to obtain the original CAD for internal structures and exterior panels prior to install interior accessories for the modified van, which is comparable to the real ambulance, and collect the data of the center of gravity, weight distribution from the seats and the installed medical equipment including the installation of the physical survival space and sensors for measuring on deformed structures during the test.

3) Conducted the rollover test of the baseline ambulance van (without reinforced structures), following the UN R66, to evaluate whether the deformation behavior fulfilling survival space requirements. Afterward we found there were some intrusions of the deformed structure into the survival space that is not met the requirement in UN R66 and subsequently we need to collect material samples for mechanical testing from undeformed structures in many parts of the van as much as possible to find further the material properties for the finite element model.

4) Simulated the 3-point bending test for the compartment pillars which are the important structures to resist the deformation from rollover test. The point of this test is to validate the finite element model and the physical test along with the available material properties and thickness, as model parameters, in a component test prior to simulate the full-scale test of the ambulance van.

5) Captured the deformation and interaction of vehicle parts and subsystems occurring during impact by correlating results of numerical simulation with those of physical test of the full-vehicle models. This will also help determine the weak areas and joints in structure which could be strengthened to ensure and improve passenger safety later.

6) Designed the new structures with reinforcement to strengthen the compartment subject to the production cost, the production capability, and the on-site installation. Then the 3D models of those were created and rollover test was simulated. The validated numerical models were used to replicate physical tests for evaluating rollover performance and to carry out design iterations in ambulance structures for meeting rollover regulation. Finally, the evaluation showed that the reinforced roll bar steel, as the additional pillar, combined with Grass Fiber Reinforced Polymer (GFRP) partition panel behind the frontal seat of the driver can strengthen the overall deformation and compliant with the requirements of UN R66.

7) Adopted the second-hand van as the second trial for the physical rollover test. But the new structure with reinforcement including interior accessories and equipment were installed to prepare the new reinforcement design of ambulance for rollover test. The result showed that the overall deformation was consistent with the one predicted in the numerical simulations.

In summary, the numerical methodology for ambulance rollover has saved time and cost in new design of the additional reinforced structures, here the roll bar steel combined with GFRP partition panel, which considerably strengthen the deformed structure in the patient compartment for rollover test. Moreover, it can be used to replicate physical tests for the modified ambulance van with consistent results in compliance with the regulation of UN R66 for rollover test.

Team research

Narong Pitaksapsin, Dr.-Ing. Sarawut Lerspalungsanti, Prasit Wattanawongsakun, Perakit Viriyarattanasak, Dr.-Ing. Chadchai Srisurangkul, Setthaluth Pangkreung, Dr. Sutee Olarnrithinun, Atapol Palasay