Even a small machinery fault, that is not be taken care of properly, can cause a severe damage to the machine resulting in unavoidable costs due to unpredicted maintenance or, even worse, loss of invaluable lives. Condition monitoring is therefore being widely deployed in several engineering fields in the last decade. Vibration analysis is one of the most popular and effective approaches for condition monitoring as it guarantees a universal deployment among different machines and failures. This can also be use as an addition system for analysis confirmation in case another different approach of monitoring is already applied, thanks to the simple system installation.

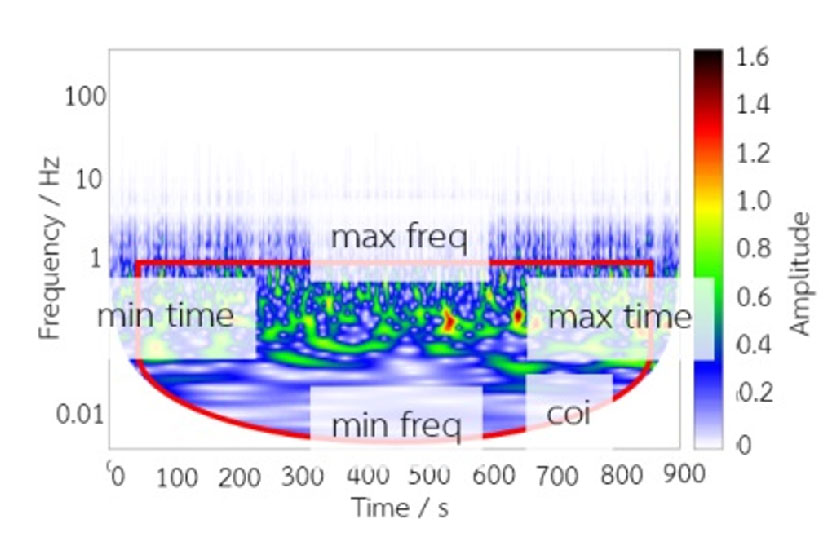

A thorough vibration analysis can be archived by a time-frequency-analysis, where the frequency components of a vibration signal or any other operational signals are visualized at a specific time. The components can be formulated either in term of amplitude or spectral energy. Changes of intensity can be used as an identification of a specific fault. Moreover, causes of abnormality can sometime be identified from the suspicious frequency. Continuous Wavelet Transform is a good approach which delivers results with wide frequency range with reasonable resolutions. Time-Frequency-Analysis can be complicated for result evaluation and may require expertises in different fields like vibration analysis as well as good know how of the inspected machine. Therefore, the results can be simplified by means of scalarized characteristic values i.e. Application Force Level acc. Heider or Tooth Force Level acc. Müller. One of the major advantages of these values is the possibility of defining evaluation boundaries, i.e. frequency range. This enables flexibility usage among different applications. The analysis can be carried out as time-efficient – for quasi-real-time application, as well as in-depth evaluation to identify a specific machinery fault.

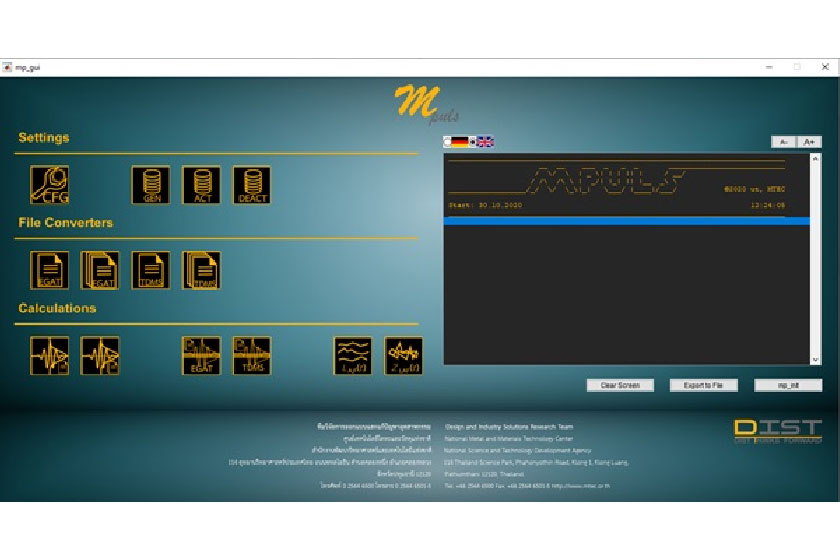

The developed approaches were implemented as an electronic data processing (EDP) tool MPULS and was deployed at North Bangkok Powerplant, where the identification of rubbing phenomenon has been in focus of monitoring. The analysis shows a good correlation with a pre-installed monitoring system by means of electrical leak current. The developed method can also be used as identification of fault position if the signal is analyzed at different positions. Furthermore, MPULS can be extended for unlimited application as the underlined comprehensive approach is universal. And the program itself can be extended ensuring flexible applications.

Research team

Dr. Chadchai Srisurangkul, Dr. Sarawut Lerspalungsanti, Thanak Utakapan, Teerapong Boonma and Foifon Srisawat