Prototype Name

Fabrication of Open-Cell Commercially Pure Titanium Foam using Slurry Impregnation Method

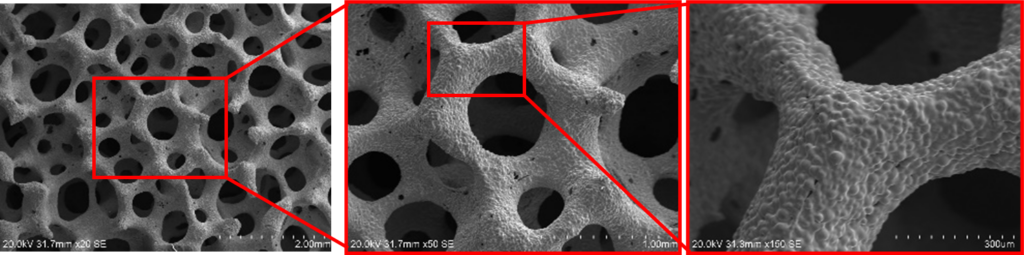

Open-cell metal foams have a connected-pore structure with high connecting porosity. Therefore, it is possible for liquid and gas to flow through but still strong enough as load baring component. Examples of applications for open-cell metal foam are high temperature filter, cathode for an electrochemical system since it has high corrosion resistance and high specific surface area, and implants since titanium has high biocompatibility. The critical mechanical properties of titanium foam are high ductility and compressibility. At above 300°C, titanium is highly active and can be contaminated easier and causes brittleness. Typical contaminations are oxygen, carbon, nitrogen and hydrogen which can find in atmosphere. Hence, the most critical factor to control is the contamination level, especially oxygen and carbon. If the contamination can be minimised, better load baring can be achieved. This developed process can produce open-cell commercially pure titanium foam with uniform structure, different pore sizes and good compressibility.

The fabrication of open-cell commercially pure titanium foam using slurry impregnation method had been continuously developed since 2007 until technology transfer in 2015. The development started with an in-house project, which results in one MTEC pending invention patent. Subsequently, Taisei Kogyo (Thailand) Co., Ltd. had two co-research projects with MTEC. The first project in 2013 is the laboratory-scale experiments at MTEC and the second project in 2014 is the implementation of pilot-scale production at Taisei Kogyo (Thailand) Co., Ltd. On the 1st June 2015, the process is transferred to Taisei Kogyo (Thailand) Co., Ltd. for commercial production. Together, there are one joint pending invention patent, two design patents, 5 publications in Q1 international journals with impact factors. The project was awarded the “Outstanding Research project FY2559” by National Research Council of Thailand.

Research team

Dr.Anchalee Manonukul, Pathompoom Srikudvien