MTEC under the stewardship of its 4th executive director and team leaders (2016-2023)

MTEC has consistently strived to develop and strengthen the materials science capabilities of the public and private sectors through its ground-breaking R&D, innovation, technology transfer, manpower, and infrastructure development efforts. All activities coherently deliver targeted dimensions such as academic excellence, responsiveness to national strategy and user relevance, impacts on economics, well-being, and competitiveness, and increasing visibility of quality and expertise. Most importantly, enhancing business and industrial competitiveness and domestic well-being development is the ultimate goal.

Dr. Julathep Kajornchaiyakul

Executive Director

Dr. Aree Thanaboonsombut

Deputy Executive Director

Dr. Kritsada Prapakorn

Deputy Executive Director

Miss Siriwan Tantawechkij

Deputy Executive Director Organization Management

(Oct. 2015-Sep. 2022)

Miss Dusadee Siamhan

Deputy Executive Director Organization Management

(Oct. 2022-May 2023)

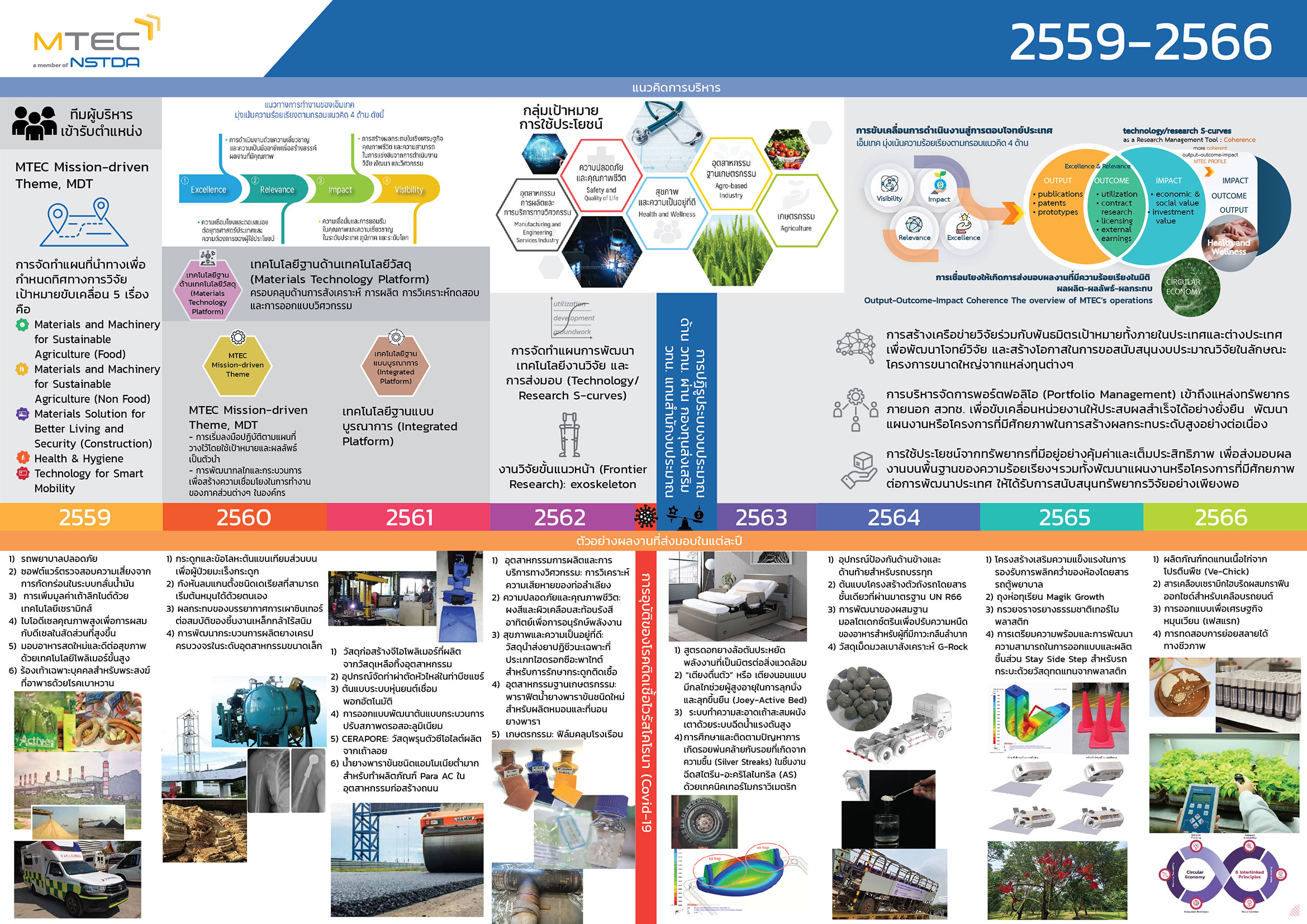

Management Overview

For decades, MTEC has coordinated with the public and private sectors, using its invaluable experience and knowledge to foresee the national dominant trends in production, agriculture, industry, and quality of life. We are committed to unleashing the capabilities of our crew members and leveraging our core competency in engineering and design to develop products that meet user expectations, especially in terms of their output-outcome-impact aspect.

The leadership team deploys research planning for commercialization to improve processes. Using the technology/research S-curve, an effective R&D management tool, they illustrate a holistic view of research and its detailed tasks, allocate resources, and create a work plan. Additionally, research support units mutually reinforce the project plan and enable us to successfully reach our target groups.

To accelerate commercialization, MTEC emphasized certain research areas under its Mission-driven Themes and country-interest strategy. Simultaneously, NSTDA has initiated a policy to foster cooperation across national research centers in fundamental research, especially through the internal sharing of common knowledge under the “integrated platform technology” program. To achieve excellence, we have embarked on frontier research in exoskeletons under the MTEC-led “Frontier Research: Exoskeleton” program, with the expectation of making groundbreaking discoveries.

Additionally, the executive team is committed to sustaining research and development to reinforce and enhance technological and engineering capabilities, from synthesis, production, testing, and engineering design. This is implemented under the fundamental technology program in materials science and new platform or technology incubation, such as additive manufacturing, dissimilar materials joining, and conductive natural rubber.

Goal-oriented Management Principles

- MTEC Mission-driven Themes

Mission-driven themes are interdisciplinary research projects across several areas of materials science. In fiscal year 2016, MTEC set an ambitious goal to foster R&D and define the trend of its mission-driven themes over a five-year period, from 2017 to 2021. Based on market and demand-pull forces, as well as global trends, MTEC’s five main research themes are:

- Materials and Machinery for Sustainable Agriculture (Food): Focus on developing materials technologies to enhance agricultural productivity and quality.

- Materials and Machinery for Sustainable Agriculture (Non Food): Focus on innovating allergen- and chemical-safe concentrated latex, comprehensive dry rubber processes, and sustainable rubber applications in local communities.

- Materials Solution for Better Living & Security (Construction): Focus on developing construction materials using finite element analysis to model different materials and predict the behavior of objects, and developing materials with environmental remediation capabilities using our signature SMARTest technology to remove, treat, and detect emerging pollutants in products and ecosystems.

- Materials Solution for Better Living (Health & Hygiene): Focus on developing personalized nutrient food and medical equipment to improve the well-being of the elderly.

- Technology for Smart Mobility: Focus on developing materials, engineering design, and testing processes to bolster domestic automobile manufacturing, particularly tires, lightweight automotive parts and high-efficiency batteries.

Aligned with global trends, Mission-driven Themes have unlocked opportunities to develop emerging technologies, such as dissimilar materials joining for automotive body structures or numerical simulation to predict new material properties by considering the process-structure-property-performance (PSPP) relationship. Additionally, additive manufacturing technologies for large-size structure fabrication, sintered-based metal additive manufacturing, wire-based additive manufacturing, and functional materials, such as conductive rubber for sensors or antibacterial composite polymer, have emerged. MTEC’s Mission-driven Themes bolster the skills and knowledge of competent researchers and promote interdisciplinary collaboration between different research groups.

- Integrated Platform Technology

Integrated platform technology is crucial for NSTDA’s long-term research and development strength. Therefore, a short-term (3-5 years) networking task force of researchers and practitioners plays a vital role. This initiative promotes collaboration and the convergence of diverse knowledge in biotechnology, materials science, electronics and computers, and nanotechnology. It provides access to broader new knowledge, technology, and prototypes, which will have a far-reaching benefit for MTEC’s Mission-driven Themes and national research themes in the future.

This dynamic helps to overcome barriers and encourages at least two national centers to collaborate in specific technology fields, such as bio-based materials, sensors, and high-performance computing (HPC) and data analytics.

MTEC leads cooperation in bio-based materials, divided into subgroups of functional additives, functional ingredients, value-added products from biomass, and biodegradation of materials.

To summarize, the overall scheme consists of three group projects and one single project:

- D-lactic acid-based copolymer process for high-potential additive applications (Group)

- Lignocellulose biomass-based carbon fiber process (Group)

- Natural rubber degrading microorganism study (Group)

- White-fleshed pomelo extracted pectin for functional substance study (Single project)

In addition to Integrated Platform Technology, advanced research on exoskeletons is an exceptionally technological progress, resulted from the collaboration between MTEC and NECTEC, in an effort to bring robotic assistance to the elderly. Thanks to our huge database of body measurements from NECTEC’s SizeThailand project, the body suit is immaculately tailored to fit the Thai elderly bodies, which could restore mobility and prevent injury. Furthermore, with NECTEC’s deep expertise in neural signal processing technology, we could expand the scope of the exoskeleton body suit to include elderly people with motor disabilities but without neuromuscular disorders, where nerves cannot carry brain messages. This would involve integrating academic studies of neural signal processing with the exoskeleton body suit to deliver supporting power to their limbs, compensating for their bodies’ shortcomings.

Rooted in outcome-oriented thinking, Integrated Platform Technology encourages exchange and cooperation between internal researchers, drives knowledge transfer and innovation, and accelerates the transformation of potential scientific advances into practical applications for Thai private sectors, benefiting all.

- Technology/Research S-curves

Technology/research S-curves are a crucial R&D management tool that provides a holistic view and organizes related activities across the organization. This results-oriented tool also supports resource allocation, task planning, and utilization.

The tool starts with the ultimate goal and creates a scheduled, step-by-step operational plan, which is fully traceable throughout the three phases: groundwork, development, and utilization.

Taking this approach will give the plan the flexibility to sharpen and update itself. However, to overcome a hurdle that stands in the way of achieving the ultimate goal, it may be necessary to rethink and recreate current knowledge with new knowledge.

Take the state-of-the-art exoskeleton project as an example. The team’s expertise is primarily in mechanics and mechatronics, which enables them to successfully pursue the goal of superb mechanical design. However, the team lacks a profound comprehension of anatomy and mathematical modeling, which is essential for developing exoskeletons that interact synergistically with the wearer. Researchers are consequently starting from scratch to coalesce mathematical simulations and computers to develop musculoskeletal modeling. Such networking activities conducted by various researchers play a key role in connecting downstream and upstream phases to overcome individual barriers and provide greater opportunities for success. Developing conductive rubber as a soft-suit sensor is another example of a notable outcome that the approach helps generate a new theme, promote the adoption of results, and boost innovation.

- Domain of Utilization

A great number of MTEC accomplishments and new promising products for future use can be categorized as follows: Manufacturing and Engineering Services Industry, Safety and Quality of Life, Health and Wellness, Agro-based Industry and Energy, Rail and Modern Transports.

Another key challenge is developing application-specific metrics to evaluate the pace of technological development. In other words, the same product that shares the same underlying technologies may require different processes or specifications for different applications. For example, agricultural non-woven fabric is different from medical non-woven fabric.

- Research and funding sources management

In 2020, the Thailand Science Research and Innovation Fund (TSRI) was established to oversee budget allocation, replacing the Budget Bureau. This restructuring posed a serious challenge to MTEC, which had to adapt its research management processes to align with the new funding sources and the country’s research budget system.

To mitigate the risk posed by the changing funding landscape, the management team emphasizes building risk awareness about the financial situation among directly related researchers and support staff. Additionally, as a committee member and secretary of the BCG (Bio-Circular-Green Economy) Model, NSTDA proactively adjusts the plan to respond to changes in capability, budget, and stakeholder requirements and constraints.

We encourage and undertake strategic alliances with global partners to develop project ideas and proposals, both applied and fundamental research. Projects with well-defined goals and objectives have a higher success rate in funding competitions.

Support staff engagement is imperative, and staff must adapt and reconsider their roles and contributions in light of new changes. Funding for research from private companies or state enterprises has dwindled and shifted to funding sources such as the Thailand Science Research and Innovation Fund (TSRI). Support staff must now play a strategic role in promoting linkages between researchers and funding sources globally.

Examples of changes in research funding sources are as follows:

(1) The grants provided by the Global Environmental Facility (GEF) Fund enable MTEC, ENTEC, and NECTEC to cope with carbon emissions, especially from transport in the tourism sector. The scheme encourages the use of more eco-friendly modes of travel, such as the railway.

(2) MTEC promotes collaboration with regulators or influencers who lack the necessary technical capabilities to carry out project tasks. For example, MTEC and the Department of Land Transport work together under the “Road Safety” scheme to address road traffic injuries and incidents.

(3) MTEC provides technical perspectives and actively participates in the project entitled “Enabling Activities to Review and Update the National Implementation Plan for the Stockholm Convention on Persistent Organic Pollutants (NIP/POPs Update)” with the Pollution Control Department (Thailand). MTEC plays a vital role in establishing an inventory of POPs and formulating the National Implementation Plan according to the Stockholm Convention.

SMARTest, a testing technique for rapidly screening the presence of persistent organic pollutants (POPs), was utilized and compiled as sufficient quantitative data. This data will be helpful for developing indicators of implementation to reduce or eliminate POPs release around the globe.

- Industry 4.0

The Fourth Industrial Revolution, or Industry 4.0, is the next massive wave of change in the manufacturing sector. It will have a profound impact on manufacturing efficiency and competitiveness. For MTEC, the adoption of Industry 4.0 principles will be driven by an Application Pull. In other words, it will be driven by changes in the operating environment, with the key roles of Trio-QCD (Quality-Cost-Delivery Time). Recent examples of Industry 4.0 in action at MTEC include: manufacturing automation, automatic machinery for agriculture, customized automatic robots, and Statistical Process Control (SPC) for an automation of aluminum casting.

- Portfolio Management

Given the constraints of task-budget-manpower, effective portfolio management can ensure an organization’s success and competitive advantage. In other words, clearly defined portfolios can significantly improve manufacturing planning and deliverability, leading to greater revenue opportunities.

Before adopting a personalized approach to systematic portfolio management, MTEC used a holistic approach, which made it difficult to address specific issues promptly. Management has made a personalized approach a focal point for the past few years. They now conduct monthly portfolio reviews at all levels of the hierarchy to identify and address issues and oversee progress, especially to ensure that revenue targets are met.

- Outcome-Impact by Design

After three research units under the umbrella of MTEC—the Life Cycle Assessment Laboratory, the Failure Analysis and Materials Corrosion Laboratory, and the Materials for Energy Research Unit—reorganized into the Technology and Informatics Institute for Sustainability (TIIS), the Rail and Modern Transports Research Center (RMT), and the National Energy Technology Center (ENTEC), MTEC’s impact was significantly reduced. One reason for this is that certain giant state-enterprises and large conglomerates, such as oil and gas titans and leading food exporters to the EU, which make up a significant proportion of the country’s GDP, are excluded from MTEC’s stakeholder engagement. Additionally, allowing sufficient time or a longer-term timeframe for the beneficial outcomes to become observable, rather than a shorter-term timeframe, is essential for this case.

To avoid the issue of undesired impact output, management uses “Outcome-Impact by Design” to develop proposals with promising high-impact and high-investment results. They first conduct an analysis to understand the components of high-impact results, and then establish criteria for evaluation. Finally, they map out the trajectory from the beginning to the end, ensuring that all components, activities, and processes are related and mutually reinforcing.

Expectation, Obstacles, and Recommendations

Conventional performance appraisal and personal progression are based solely on the “3Ps”: papers, patents, and prototypes. This approach is arguably too narrow, as it only measures knowledge creation and short-term performance. It does not adequately reflect overall long-term performance, which takes outcome and impact into consideration. Additionally, there is insufficient evidence to suggest that the benefits of performance appraisal that includes outcomes and impacts outweigh the costs of traditional 3P performance appraisal. This makes steering organizational culture toward a new concept of performance appraisal an arduous journey.

To implement an outcome-oriented organizational culture, MTEC must establish effective performance management and develop an understanding of the importance of the results chain framework, which is a sequential progression of performance comprising outputs, outcomes, and impacts. The support team plays an important role in following up on research output to ensure commercialization or public benefits outcomes and impacts, and in supporting the implementation to commercialization.

In a country with a successful R&D ecosystem, strong collaboration and expertise exchange between partners is key to expediting the translation of basic research and innovation into commercialization. Unfortunately, Thailand’s R&D ecosystem is not yet fully developed, and it is necessary to attract all required competent partners to create an R&D-facilitating network. NSTDA previously identified KPIs that overemphasized metrics like technology-based R&D. To propel the nation, MTEC should build an R&D ecosystem that fosters incubation, development, and utilization.

Currently, none of MTEC’s research groups can carry out the full spectrum of research and development. MTEC’s role is simply to contribute to each segment of the R&D ecosystem. Recent examples of our collaboration include participation in the upstream and midstream phases of natural rubber latex technological development, such as the development of new alternative preservatives for extending the shelf-life and low-chemical natural rubber latex. Healthcare innovation is another example, including beds for the elderly and rehabilitation, food innovation, and so on.

Considering the industrial structure will be essential for MTEC to make informed decisions and determine a strategic direction in the future. It is true that an industrial structure facilitates the display of an entire value chain. Given that the value chain corresponds with MTEC’s manpower capability, cost of capital, key technological partners, and stakeholders, we can redefine its role in delivering high-value outputs with significant quantity dimensions.

8 years of pride

We are thrilled to celebrate 8 years of management, and immensely proud of our team's unity, endeavor, rationality, team spirit, and adaptability in times of crisis. Also, the growth of high-caliber young researchers and their works is awe-inspiring. Their work, developing to commercialization, is creating a dramatic impact on our country for many years to come.