Lightweight structural parts for high performance electric powered two-wheeled vehicle

Zapp Electric Vehicles is originally a start-up company registered in United Kingdom. The company cofounders, comprised of primarily Thais, have a target of developing a high-performance electric powered two-wheeled vehicle to be exported for commercialization in UK and Europe. With a need to acquire a technical prototype for further rounds of fundraising, the company contacted MTEC research teams with capability and experience in energy storage system and mechanical engineering fields for a consultation project to design and develop a prototype of high-performance EV scooter. The project involved a structural design and analysis of a main body component made from lightweight materials, electrical system design and integration, and design utilization of portable battery packs.

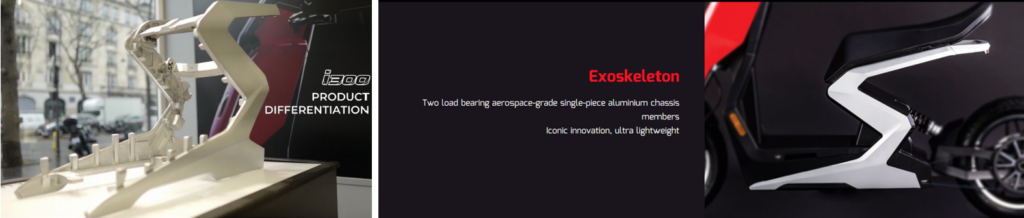

Details of the exoskeleton-type chassis frame in the Zapp i300 from the project

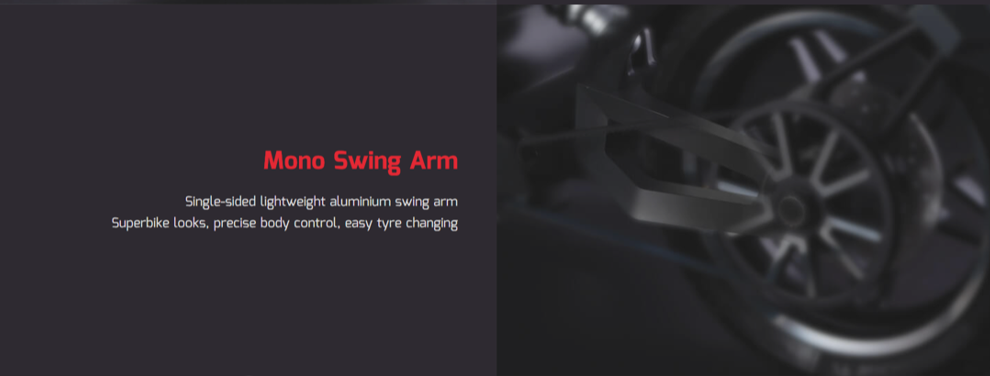

Rear suspension components in the Zapp i300 from the project

A finite element analysis was used for structural analysis of body components and their joint connections to estimate resulting stresses, deformations from external loads in real applications. Two components were studied, i.e., a main body structure (exoskeleton) and a swing arm. The main technical challenge for this project was to achieve a design for component that boosted modernization as well as retaining a required engineering strength/functionality and also being lightweight. Thus, aluminum was the material of choice along with a design concept of a load bearing exoskeleton to replace a conventional approach of deformed steel pipes for the main body frame of the EV scooter. Topology optimization technique was then employed to obtain a lightweight design of both exoskeleton and swing arm components while also still satisfied a conceptual appearance of the product.

Both components were analyzed and determined to be engineering sound with a resulting factor of safety higher than 4 in all case studies under an external load of two passengers (150kg). Furthermore, both components have been approved and taken into a production line by the company. They are now selected and presented in the i300 product commercially available on https://zappev.com/. Moreover, the i300 EV model has been field tested at maximum speed of 96 km/h. Additionally, Zapp Electric Vehicles has recently been listed in NASDAQ (NASDAQ:ZAPP).

Research team

Dr. Chi-na Benyajati, Dr. Pimpa Limthongkul, Dr. Jiravan Mongkoltanatas, Dr. Ukrit Sahapatsombut, Piyapong Premvaranon, Jenwit Soparat, Apichart Teralapsuwan and Wuttipong Sritham