Slag deposition sensor

One of the main problems currently facing coal-fired power plants is the handling of combustion ash deposits attached to the furnace walls. These ashes are called Water Wall Slag. The accumulation of ash on the boiler heat exchanger tubes hinders heat absorption and can damage the boiler if the ash becomes thick enough to collapse. In that case, it will endanger the boiler tubes of the power plant and damage the boiler, so it is necessary to stop the power plant operation.

The system for removing the ash accumulated on the boiler wall is a system called “Water Soot”, which sprays water from a device similar to a large water nozzle installed on the boiler wall. In the cleaning process, in order to remove the slag, water will be shot to a position on the other side of the boiler wall, where ash accumulates. This process occurs while the power plant is producing electricity (load-on) and to remove ash accumulated in the process of power generation. When spraying water to clean the furnace wall, the data from the sensor is used to identify the location or area where ash accumulates. This kind of sensor is called a slag deposition sensor. However, the sensors are expensive, and a large number of sensors need to be installed to cover the area of the boiler wall. The traditional sensor installation will have certain risks in the process of installing the sensor on the boiler tube wall because it is necessary to cut and weld the boiler tube and then install the sensor on the boiler tube. The service life of the sensor is limited.

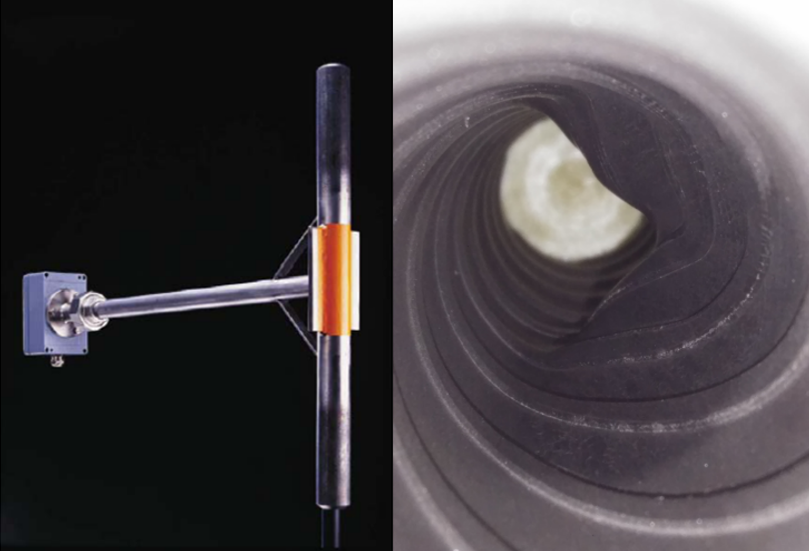

Clyde Bergemann Sensor and inner surface of the pipe after installation.

This prototype of the slag deposition sensor aims to estimate the amount of ash deposited on the boiler wall. The design allows for less complex technology to be manufactured than the main sensors on the market, thus making the price cheaper. We designed the sensor to make it easy to install without cutting off the boiler tube during installation, to limit the risk of boiler leakage. The prototype of the slag deposition sensor is designed to have a longer service life than the traditional sensor used in the market, which limits the original weakness of the signal wire is very small. So it is easy to be corroded and damaged.

The developed sensors were tested under the actual operating conditions. They were installed on the boiler walls of Mae Moh Power Plant, production unit 11, totaling 8 sensors during the shutdown of the power plant between 10 February-9 March 2018. After satisfactory test results, 96 additional sensors were installed in February 2020, which were used as the measuring devices for the ash deposition on the furnace wall for the focus clean system of the water soot system in the power plant unit 11. The achievements were further expanded with the installation of an additional 12 sensors in the MM-T1 power plant in July 2020.

Research team

Dr. Nirut Naksuk, Dr. Chatchai Suksrimuang, Jiradech Nakngoenthong, Chaiyan Sakunpet-alam, Narongkorn Pattaramas, Waravut Printrakoon and Rattanapon Yuttawiriya