System Prototype Wet Ash Monitoring on Submerged Scraper Conveyor

Submerged Scrapper Conveyor (SSC) is a two-way conveyor for bottom ash handling. In the event that large amount of slag falls over onto SSC System in a short period of time, rapid increase of wet ash on the SSC as a result of slag fall posts serious rise to power plant operation. If the SSC speed was not adjusted accordingly within this critical period, accumulation of wet ash in the well under the boiler will excess of the capacity that the SSC can handle at maximum hydraulic pressure. This event will eventually results in the reduction of production capacity and finally force the operator to shut down the power plant, causing losses to the electricity production.

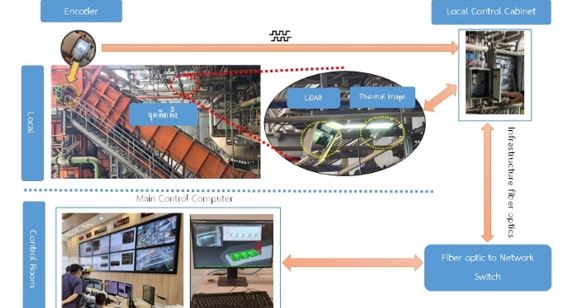

The objective of this research project is to solve the overload SSC problem by monitoring the wet ash on the SSC system real-time using Machine Vision technology, LiDAR Sensor and thermal imaging. This sensor fusion technology will help the operator monitoring the amount of wet ash on the SSC in real-time thus allowing them to adjust the speed of the flight bar via chain speed control in a timely manner. This new technology reduces the risk of having to shut down the power plant from the SSC overload.

Research team

Dr.Chatchai Suksrimuang, Dr.Nirut Naksuk, Chaiyan Sakunpet-alam, Narongkorn Pattaramas, Jiradech Nakngoenthong and Waravut Printrakoon