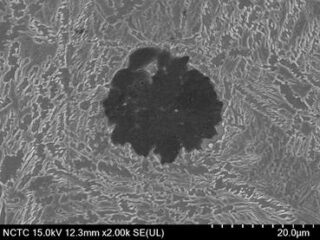

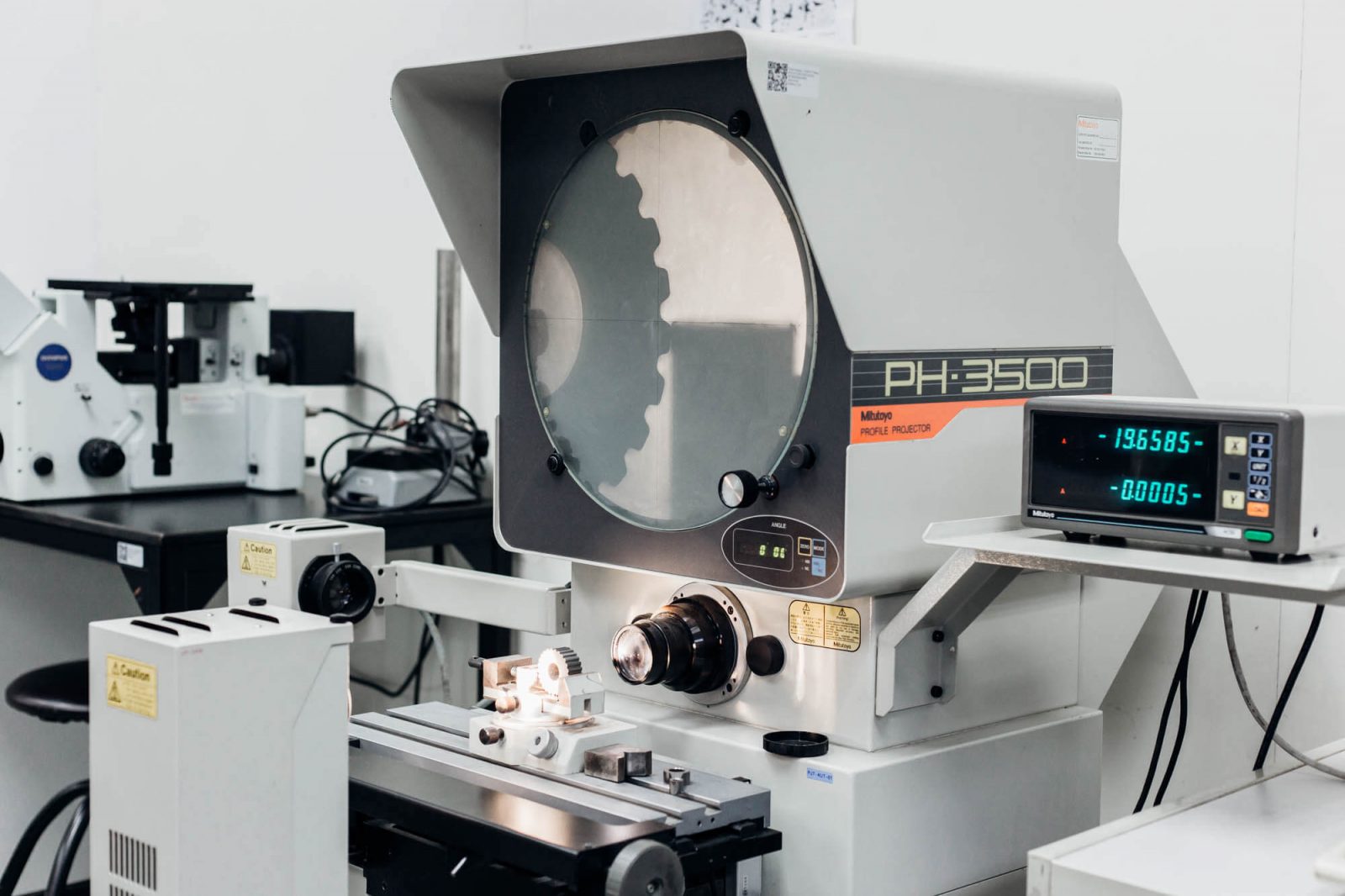

The Particulate Materials Processing Technology Research Team conducts research and development in sintered advanced steels, high-entropy alloys, new generation materials, functional materials, and new production process, such as additive manufacturing and aluminum foam manufacturing.

Our research works consist of basic research to build knowledge on basic metallurgy processes and applied research to meet the need of metal industries and alloys.

• The development of bevel gear forming process with powder metallurgy (Dr. Ruangdaj Tongsri)

• The improvement of strength and ductility of sintered materials from low carbon steel powder (Dr. Ruangdaj Tongsri)

• Sintered materials for microorganisms disinfection

• Alternative materials for rail transport systems

• Phase changes of new sintered steels

• Design and manufacturing of self-lubricating composites

• Aluminium foam for industrial applications (Dr. Sompong)

• Gas-sprayed powder metallurgy

• Metal powder mixers and powder metallurgy

• Compression molding machines for the size of 100 tons (Made in Thailand) and 50 tons (Dorst, Germany)

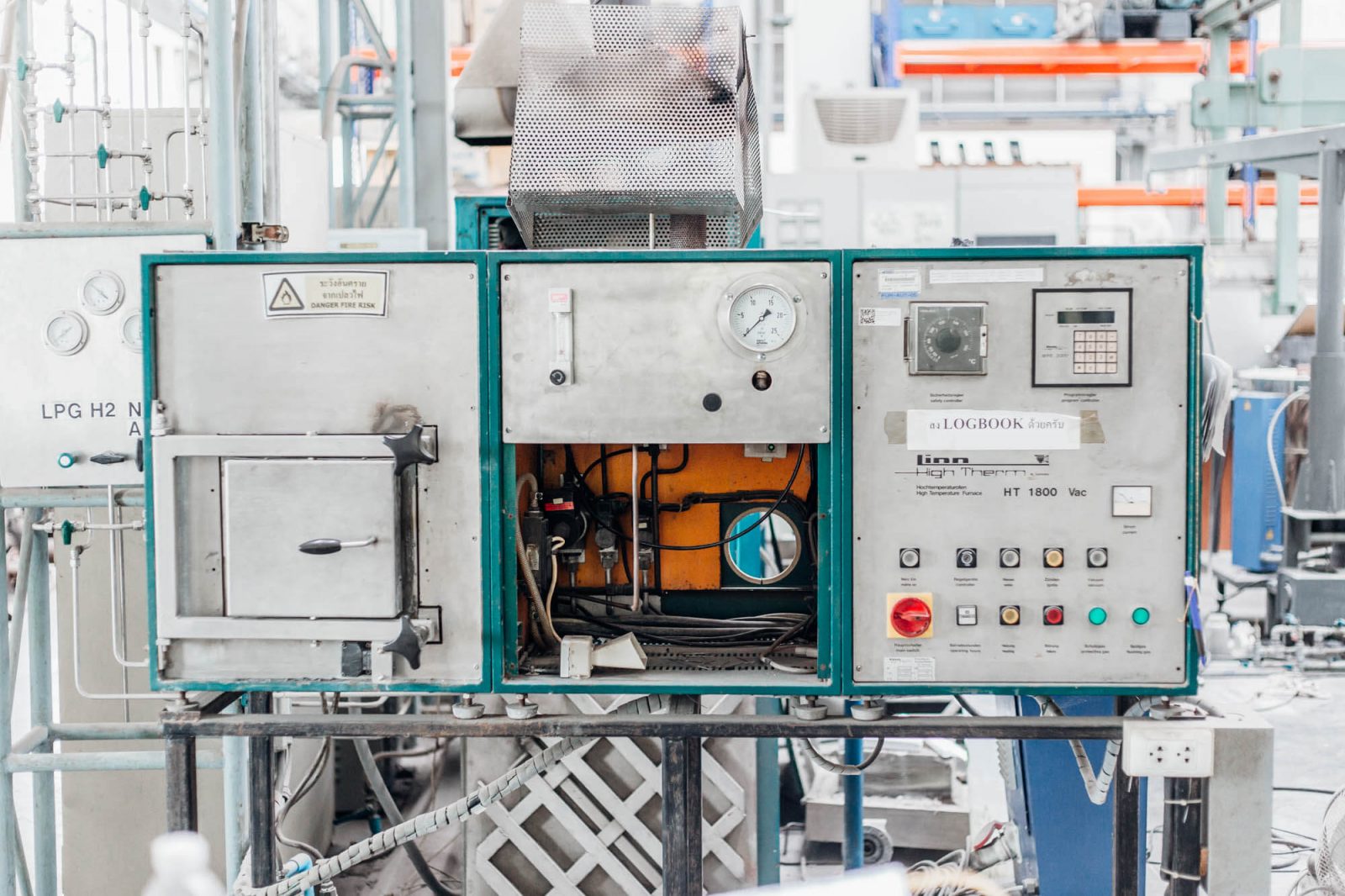

• Catalytic interface removal furnace

• Batch sintering furnace and vacuum furnace

• Powder metallurgy injection molding machine

Puangporn Puntumakoop (Senior Analyst)

Tel: 66 2564 6500 ext. 4784, 668 1817 0415

Fax: 66 2564 6504

Email: puangpp@mtec.or.th