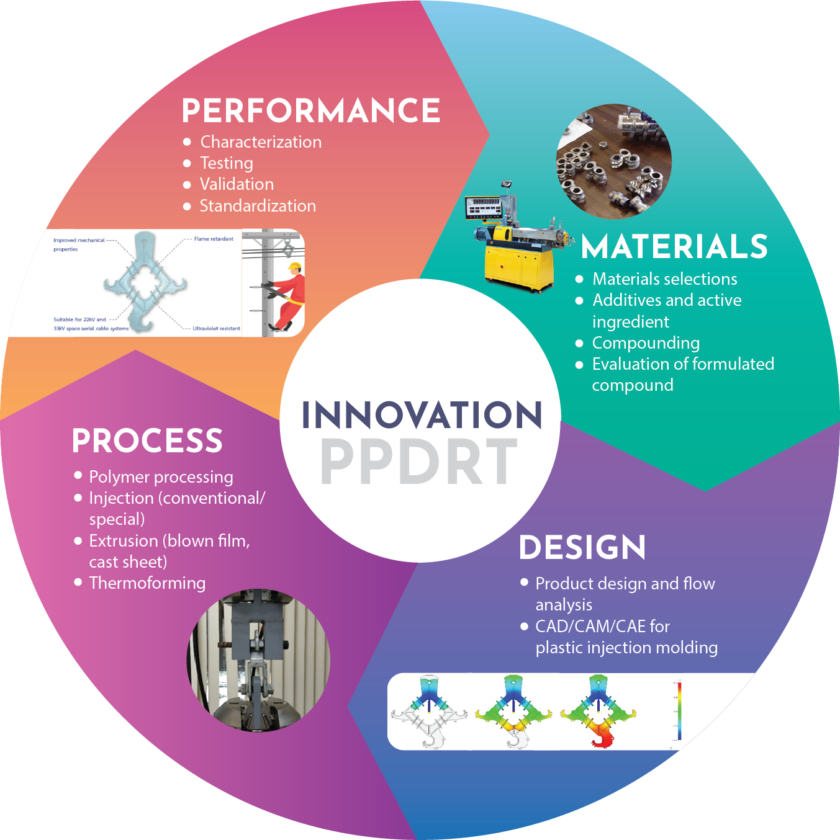

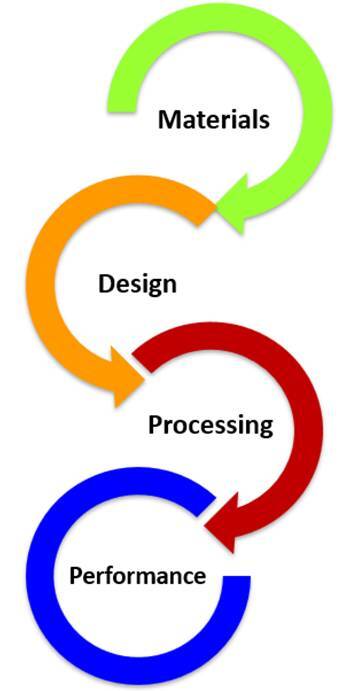

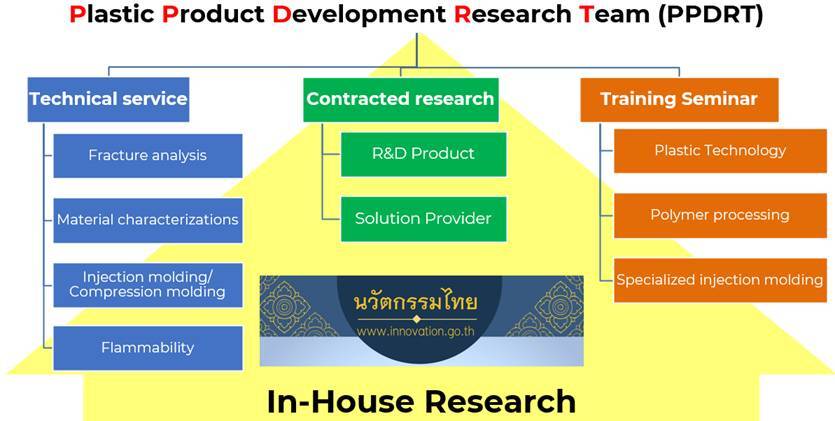

Plastic Product Development Research Team conduct research and development activities and providing technical services based on the competence and expertise of personnel appropriate application of modern technology availability of tools, machines and analytical equipment Basic properties of materials to build a knowledge base and skills in the development of materials and technologies in the production of various plastic products that meet the needs of users. Capabilities and activities of Plastics Technology Laboratory, It includes a range of areas including material selection and development, plastic product design and development, development of plastic molding process and analysis and testing of plastic products.

Materials Selection and Compounding

– Active Functions

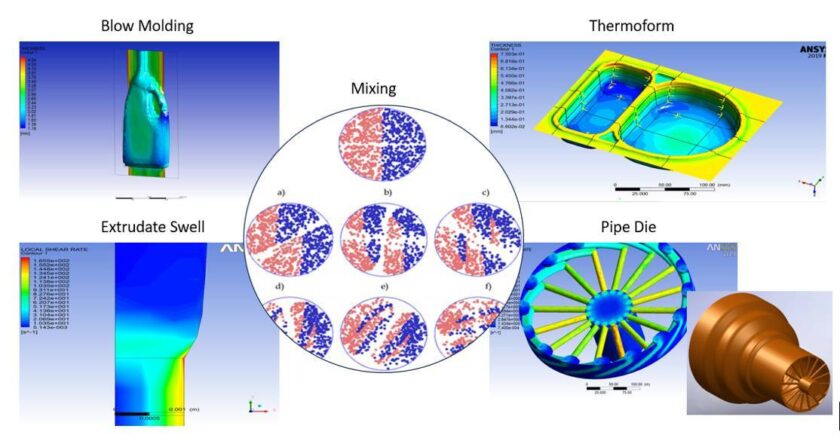

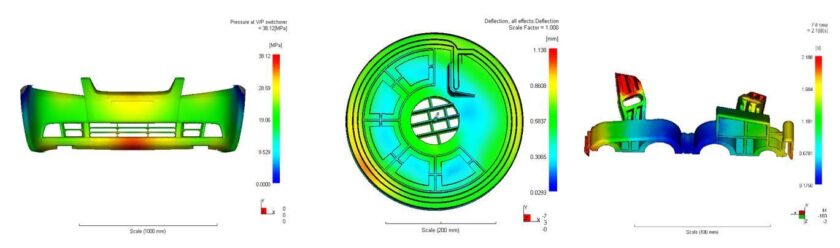

Product Design and CAE for Plastic Processing

– CAD/CAM/CAE for Plastic Extrusion & Injection molding

Polymer Processing

– Injection and Compression molding (Conventional and Special)

– Extrusion

Characterization

– Testing

– Validation

– Standardization

- Polymer composite materials from natural resources

- HDPE pipe products from high-quality reworked materials

- Development of HDPE cable spacer and snap ties for provincial electricity authority (PEA)

1. Development of snap-ties using TPU compound

2. Development of plastic cable spacer using HDPE compound

3. Improve the quality of Spaced Aerial Cable (SAC)

- Plastic Extrusion Simulation and Die Design

- CAE for Plastic Injection Molding

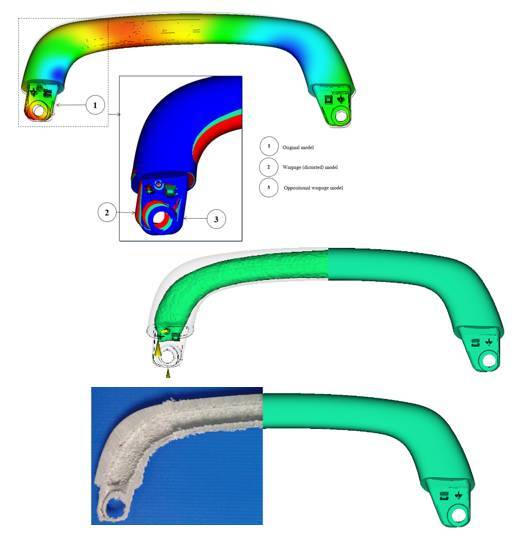

- Design and manufacturing of hybrid grip assist handle using Gas-assisted injection molding

- Product design and simulation of plastic extrusion & injection processing

- Development of Plastic Blends and Compounds

- Plastic Processing

- Material Properties and Product Testing

Kanokporn Mansakul (Analyst)

Tel: 0 2564 6500 ext. 4305

E-mail: kanokpom@mtec.or.th