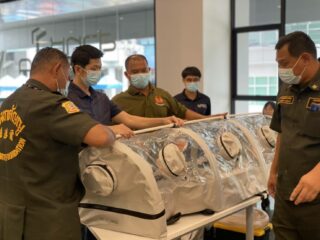

On April 29, 2021 at NSTDA Yothee Building, Rama VI Road, Bangkok

Mrs. Kullaprapa Navanugraha, Vice President of NSTDA, and Dr. Sarawut Lerspalungsanti, Research Team Leader of Design and Industry Solutions Research Team, Engineering Design and Computation Research Group of MTEC had delivered the ‘PETE’ Patient Isolation and Transportation Chamber to the hospitals and related agencies to support the medical personnel during the relocation and treatment of COVID-19 patients.

Mrs. Kullaprapa Navanugraha, Vice President of NSTDA, said that the medical device industry is part of the healthcare industry in new target industries (New S-Curve) to drive Thailand to become a world-class medical hub in ASEAN. In order for Thailand to achieve that ambitious goal, the country requires advanced knowledge and expertise in science, technology, and innovation as a mechanism for enhancing the abilities of its healthcare industry. NSTDA, therefore, aims to develop science and technology to foster innovations that will add benefits for the economy and society of Thailand. NSTDA possesses a solid foundation of science and technology that could help increase the competitiveness of the healthcare industries conforming to the Ministry of Higher Education, Science, Research, and Innovation, and government policies on the BCG Economy Model by focusing on boosting economic growth, and natural, environmental, and industrial sustainability.

NSTDA has developed research and innovations to counteract the COVID-19 pandemic and delivered more than 20 research outputs to the hospitals and related agencies. The delivered research works covered the prevention and reduction of disease infection, proactive screening, and basis diagnosis, as well as technology transfer for the entrepreneurs in Thailand.

The developed PETE can help prevent the COVID-19 infection to the medical personnel and devices. MTEC had delivered 5 sets of the PETE to the Faculty of Medicine Vajira Hospital, Navamindradhiraj University, Erawan Field Hospital 2 of Wetchakarunrasm Hospital, Ruamnamjai (Klongtoey) Foundation, Vibhavadi Hospital, and Saint Mary’s Hospital to support the medical personnel during the relocation of COVID-19 patients to various places without moving the patient out of the chamber.

Dr. Sarawut Lerspalungsanti, Research Team Leader of Design and Industry Solutions Research Team, Engineering Design and Computation Research Group of MTEC said that the PETE (Patient Isolation and Transportation Chamber) is one of the devices that was developed to prevent the spread of the pathogens during a patient transfer. Currently, the common negative pressure chambers were expensive and had various limitations. MTEC research team, therefore, had developed the PETE, a device for transferring patients with respiratory tract problems. The PETE consists of 2 main parts; the first one is a clear plastic capsule (also called chamber) that fits the patients’ body, and the second part is a negative pressure unit designed to control the air circulation inside the chamber when the patient is placed inside and the zipper is closed. Then, the medical personnel will turn on the automatic pressure adjustment system to allow the outside air to flow into the chamber, so that the patient can breathe normally. When the air passes through, the patient may release pathogens while breathing out, but that contaminated air will be sucked into the HEPA Filter (High Efficiency Particulate Air Filter) to filter out germs and sterilize them with the UV-C light before being released to the outside. The PETE also has areas for threading the ventilator and saline line of the patient, and 6 surgical gloves around the chamber for ease of medical treatment.

The PETE also has a smart controller system to control the pressure inside the chamber. The system can be easily used both on the ground and on the flight, and there is a pressure alarm to warn of air leaks, and a monitoring sub-system to remind for air filter replacement. All of these features directly benefit the patients’ safety. The PETE chamber likewise can be put into the X-ray machine and CT scan since it does not contain any metal part. The patients, therefore, do not have to move out of the chamber as compared to other devices. This helps reduce the chance of the spread of infection to various medical equipment and air conditioning systems within the hospitals. Furthermore, the chamber is lightweight and can be folded into a bag, which can be easily handled and reinstalled, especially in the ambulance. That is to say, if the medical personnel use the PETE to move patients from place to place, it will not only help limit the spread of infection but also reduce the risk towards the medical personnel and other people in the hospital.

Assoc. Prof. Dr. Anusang Jitsomkasem, Deputy Dean of the Faculty of Medicine Vajira Hospital, Navamindradhiraj University, gave an advise on the cleaning and disinfecting process of the PETE. The research team, therefore, had applied a nano automizer with benzion sanitizer developed by NANOTEC to clean the chamber and the results turned out satisfactorily within 10 minutes.

Assoc. Prof. Dr. Anusang Jitsomkasem said that during the COVID-19 pandemic, the PETE is crucial as it helps reduce the infection, numbers of medical personnel while transferring patients, and time, as well as protect their safety while taking good care of the COVID-19 patients. He recalled that face mask shortage was once a big problem during the earliest stage of the pandemic. Thailand also suffered from the expensive cost of the imported medical equipment, especially the PETE, of which the price was increased to around seven hundred thousand baht, even though the cost of production is about compared to a hundred thousand baht. Therefore, the PETE developed by MTEC is an innovation that will suit the manufacturers to develop and produce local medical devices.

At present, The PETE is a Thai research result that passed the ISO 14644 and in the process of establishing the International Electro Technical Commission (IEC) 60601-1, and Suprera Innovation Co., Ltd. is recently a licensee for the technology transfer of the PETE’s production and distribution.