The National Metal and Materials Technology Center (MTEC), NSTDA, has conducted research and developed light-responsive organic materials for measuring ethanol levels in fuel under the collaboration of the Ministry of Higher Education, Science, Research, and Innovation (MHESI), the National Science and Technology Development Agency (NSTDA), and Thammasat University (TU). All stakeholders have signed a memorandum of understanding with PTT Public Company Limited to jointly research and develop renewable energy technologies and innovations for sustainability under biotechnology, food technology, computer and electronics technology, metal and material technology, energy, and nanotechnology.

[Source: https://www.nstda.or.th/home/news_post/pr-nstda-mou-29022567]

Dr. Thanasat Sooksimuang, a senior researcher and head of the Functionalized Material Innovation Research Team, Advanced Polymer Technology Research Group at the National Metal and Materials Technology Center (MTEC), NSTDA, leads a collaborative research project to develop a measurement system for analyzing ethanol in fuel oils at desired positions. He stated that initially, the MTEC research team collaborated with the National Electronics and Computer Technology Center (NECTEC), the National Center for Genetic Engineering and Biotechnology (BIOTEC), and Thammasat University through a joint research project under the International Joint Research Center on Food Security (IJC-FOODSEC). At that time, the research was not directly related to the method of measuring ethanol in fuel oils. The research team, however, received industry feedback regarding the need for a simple and convenient method for measuring ethanol in the food industry. The traditional method involved the use of chemicals that could be highly toxic and time-consuming. Therefore, the feasibility of using fluorescence technology is assessed to measure ethanol levels in specific food industries, providing preliminary knowledge.

Early in the collaboration with NECTEC, a visit by PTT Public Company Limited (OR) leadership to NSTDA revealed a research need. They sought a simpler, more convenient, and cost-effective method for measuring ethanol levels in fuel oils compared to the current method. Accurately measuring ethanol levels in fuel oils is critical. In gasohol, for example, exceeding or falling below standard ethanol content can negatively impact engine performance. To ensure quality control in this area, PTT Public Company Limited seeks a more efficient method.

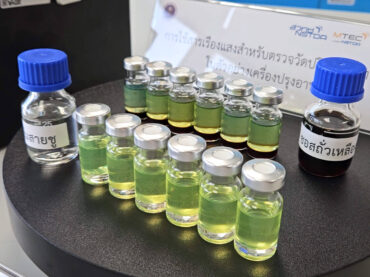

Then, MTEC and NECTEC research teams collaborated to conduct the feasibility study of using fluorescence sensing technology to analyze ethanol in fuel oils to address the company’s needs. The research team also engaged in discussions with the company’s research team to address other important issues. During a visit to NSTDA, PTT leadership saw MTEC and NECTEC’s promising technology that addressed their need for ethanol level measurement. This led to cooperation in a joint research project to develop a measurement system for analyzing ethanol in fuel oils in situ. The objective is to develop a practical measurement system to be used in the field. The measurement system comprises fluorescence sensing agents, which the MTEC research team has developed, capable of undergoing photochemical changes when exposed to an environment containing ethanol. These work together with portable miniature spectrophotometers developed by NECTEC.

Dr. Thanasat explained that the project plan is divided into 3 phases. The first phase involves developing the hardware and chemical systems and producing approximately 10 prototype devices. Meanwhile, the chemical substances will be formulated in a state and packaging ready for use, which can be used for testing for approximately 3 months. These will then be delivered to the company for actual testing to assess the measurement system’s performance and identify any operational issues that need further development. The measurement system will be further developed in the second phase to meet the actual user needs better. Additionally, for the chemical substances, apart from being ready for actual use, stability studies will be conducted to determine factors such as shelf life and how well they can be stored as chemical substances and samples to facilitate future testing when necessary.

As for the third phase, the project aims to expand the development of the chemical analysis system and the reading device to meet long-term standards for use within Thailand, at regional levels, or even globally. Currently, the research team has developed a ready-to-use tool that works in conjunction with the developed chemical substances, addressing the needs outlined by PTT, which has been providing challenges to the research team since the beginning. The measurement of ethanol levels in fuel oil can now be achieved satisfactorily, meeting the requirements.