Development on the Prototyping Process of Conversion of Aluminum Dross

Development on the Prototyping Process of Conversion of Aluminum Dross

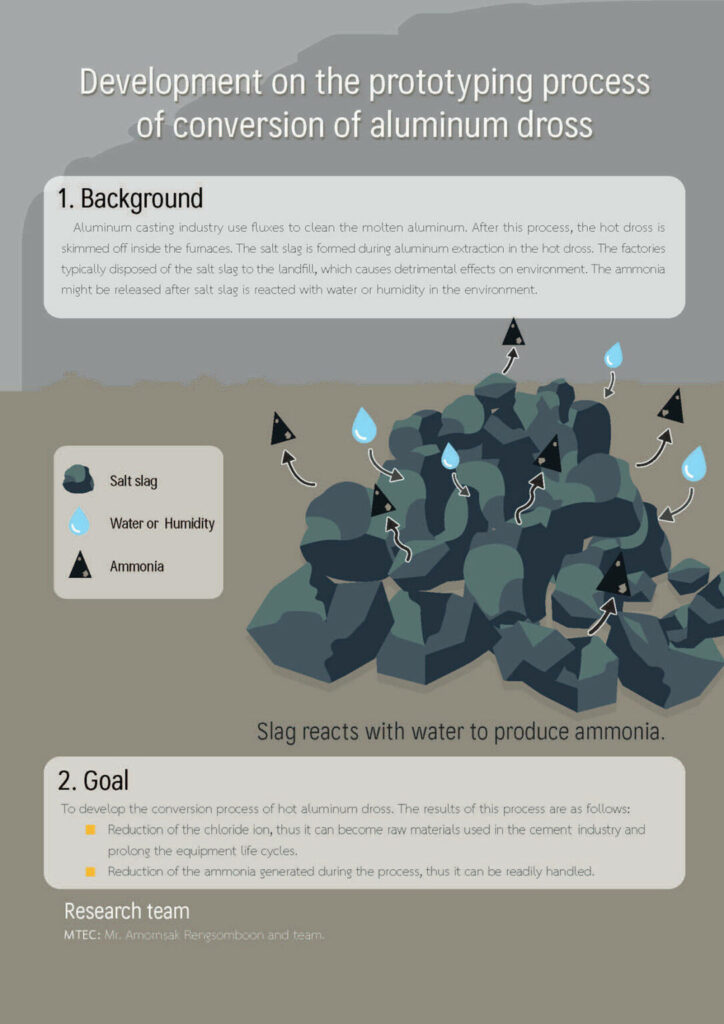

Background

Aluminum casting industry use fluxes to clean the molten aluminum. After this process, the hot dross is skimmed off inside the furnaces. The salt slag is formed during aluminum extraction in the hot dross. The factories typically disposed of the salt slag to the landfill, which causes detrimental effects on environment. The ammonia might be released after salt slag is reacted with water or humidity in the environment.

Goal

To develop the conversion process of hot aluminum dross. The results of this process are as follows:

– Reduction of the chloride ion, thus it can become raw materials used in the cement industry and prolong the equipment life cycles.

– Reduction of the ammonia generated during the process, thus it can be readily handled.

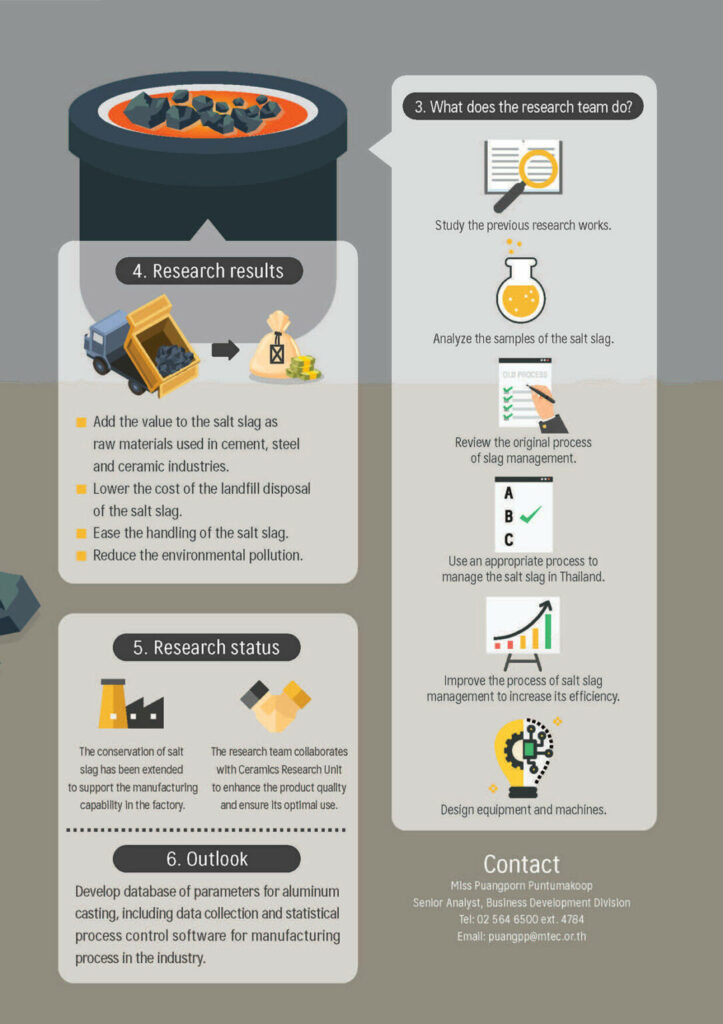

What does the research team do?

– Study the previous research works.

– Analyze the samples of the salt slag.

– Review the original process of slag management.

– Use an appropriate process to manage the salt slag in Thailand.

– Improve the process of salt slag management to increase its efficiency.

– Design equipment and machines.

Research results

- Add the value to the salt slag as raw materials used in cement, steel and ceramic industries.

- Lower the cost of the landfill disposal of the salt slag.

- Ease the handling of the salt slag.

- Reduce the environmental pollution.

Research status

- The conservation of salt slag has been extended to support the manufacturing capability in the factory.

- The research team collaborates with Ceramics Research Unit to enhance the product quality and ensure its optimal use.

Outlook

Develop database of parameters for aluminum casting, including data collection and statistical process control software for manufacturing process in the industry.

Researcher team

MTEC: Mr. Amornsak Rengsomboon and team

Contact

Miss Puangporn Puntumakoop, Senior Analyst, Business Development Division

Tel: 02 564 6500 ext. 4784

Email: puangpp@mtec.or.th