Food Structure Design

Food Structure Design

At present, the market for healthy and nutritious food products are continuously growing. These kinds of foods includes natural food products that are nutritious, non-allergenic, fiber-rich, high-protein, and low-fat, and may possess micronutrients and bioactive compounds. However, most healthy food is normally inferior in taste, texture, and stability compared to conventional food, which can affect the consumer’s acceptance.

Food structure design is one of the technologies used to create and control food texture, shape, smell, and taste to be comparable to those of the original food. The use of this technology to develop healthy food requires a multi-disciplinary knowledge, with materials science and engineering at its core.

Food is a complex material that contains different kinds of components and structures. Therefore, food structure design involves the selection of food ingredients and food processing, which will ultimately control the food texture.

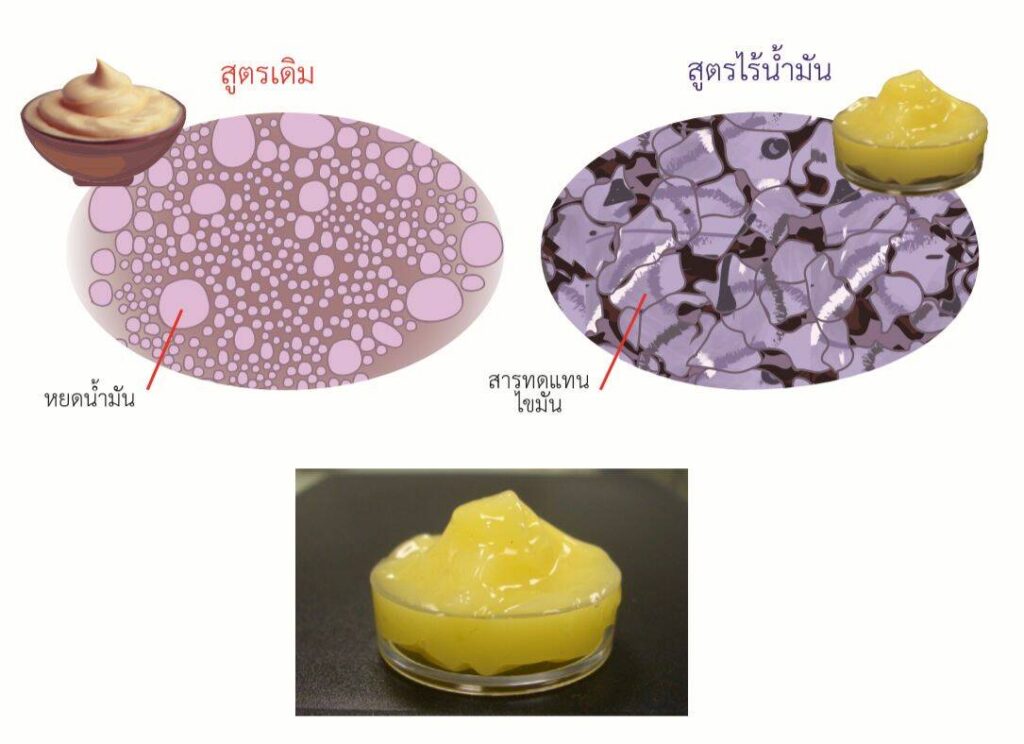

Healthy food, such as low-fat products has been created by food structure design technology developed by the Food Materials Research Team of MTEC. Our technique employs the addition of dietary fat substitutes and natural texture modifiers (hydrocolloid) with its qualities comparable to fat-rich food.

Noted examples of food developed by the research team in collaboration

with the private companies, are as follows

- Low-fat sausage: This product contains fat less than 5%, whereas the original sausage contains fat in the range of 20-30%. Animal fat yields good taste, but quite unhealthy. The use of fat substitutes not only reduces fat but also increases dietary fiber.

- Oil-free mayonnaise and salad cream products: This product employs a natural texture to help adjust the viscosity (rheological properties), stability, and taste modifiers to be comparable to fat-rich mayonnaise and salad cream.

Mayonnaise and salad cream products without oil

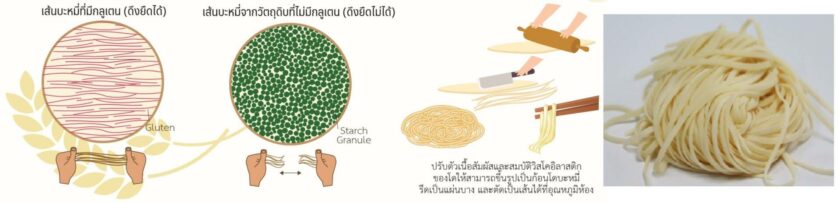

- Gluten-free food: These products include bread, sandwiches, croissants, and noodles. These kinds of food are normally made from wheat flour that contains gluten, which makes food more elastic, stickier and softer. However, there are an increasing number of consumers with gluten intolerance or patient with celiac disease; the research team, therefore, develops gluten-free products by using rice flour and cassava flour as the main components. The products also possess a combination of natural starch, modified starch, and food hydrocolloid, which makes bread and croissant to become softer since the gas properly during the fermentation is maintained, thus no crumbling and good-quality texture result.

Bread with gluten-free

- Gluten-free dough and noodles: These products can be stretched in the calendering process, cut into strips and melted solids while boiling, thus the finished products will have good shape and texture, and can provide satisfying sensory qualities to consumers.

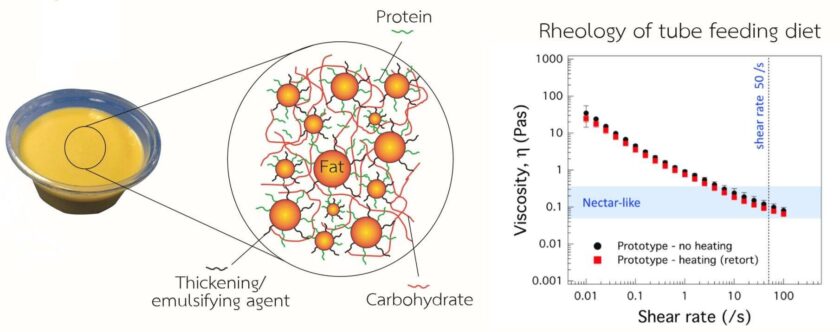

Food products for specific groups of consumers: An example of these products include a blenderized diet for the elderly, bedridden patients, as well as people with severe swallowing conditions (tube feeding). The development of this food will demand the consideration for the need of sufficient nutrition for health and body, the appropriate flow behavior of tube feeding patients, and the stability in the heat sterilization process and the storage.

Easy-to-chew meat: This product is in the form of steaks from beef and ground pork. It is created by using structural design and texture adjuster to make meats softer with good shape, chewable, and easy to swallow. The meat, therefore, is suitable for the elderly and people who have chewing problems.

Steaks from beef and ground pork

At present, the research team has been exploring the use of 3D printing technology to mold the food structure for the development of personalized diet to support various groups of consumers, such as elderly, patients, and athletes. Moreover, the research team also improves the use of food texture adjustment technology with the extrusion process to design meat from vegetable proteins to create texture and qualities to be comparable to those of the original meat.

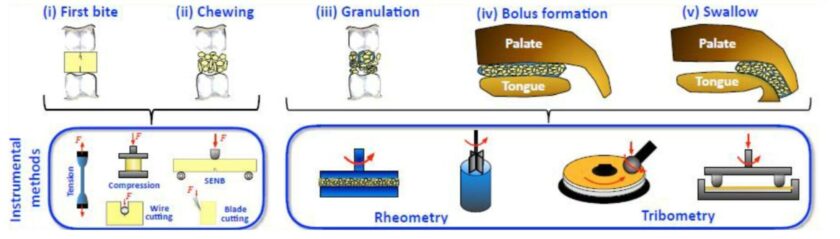

In addition to the development of healthy food with technology and food structure design, the research team also studies the food oral processing, which involves the study of food mechanics, food rheology, and food tribology. These studies yield created an understanding of the food chewing process, food bolus, and the character and behavior of the bolus before swallowing. A complete understanding of food oral processing is critical to the development of food with good

Image from: Stokes, J. R., Boehm, M. W., & Baier, S. K. (2013). Oral processing, texture and mouthfeel: from rheology to tribology and beyond. Current Opinion in Colloid & Interface Science, 18, 349–359.

The absorption of useful nutrients into the body is an important process, therefore, the research team will study the digestion and absorption of nutrients from healthy products using the Simulated Gut Model. The received information will ensure the consumers that they are consuming healthy food that has good texture and taste with appropriate nutrients and bioactive compounds.

Image from https://www.thetimcompany.com/

An image of the Stimulated Gut Model for the study of the digestive process in the alimentary system by stimulating the function of the stomach, small intestine, and the absorption of large intestine.