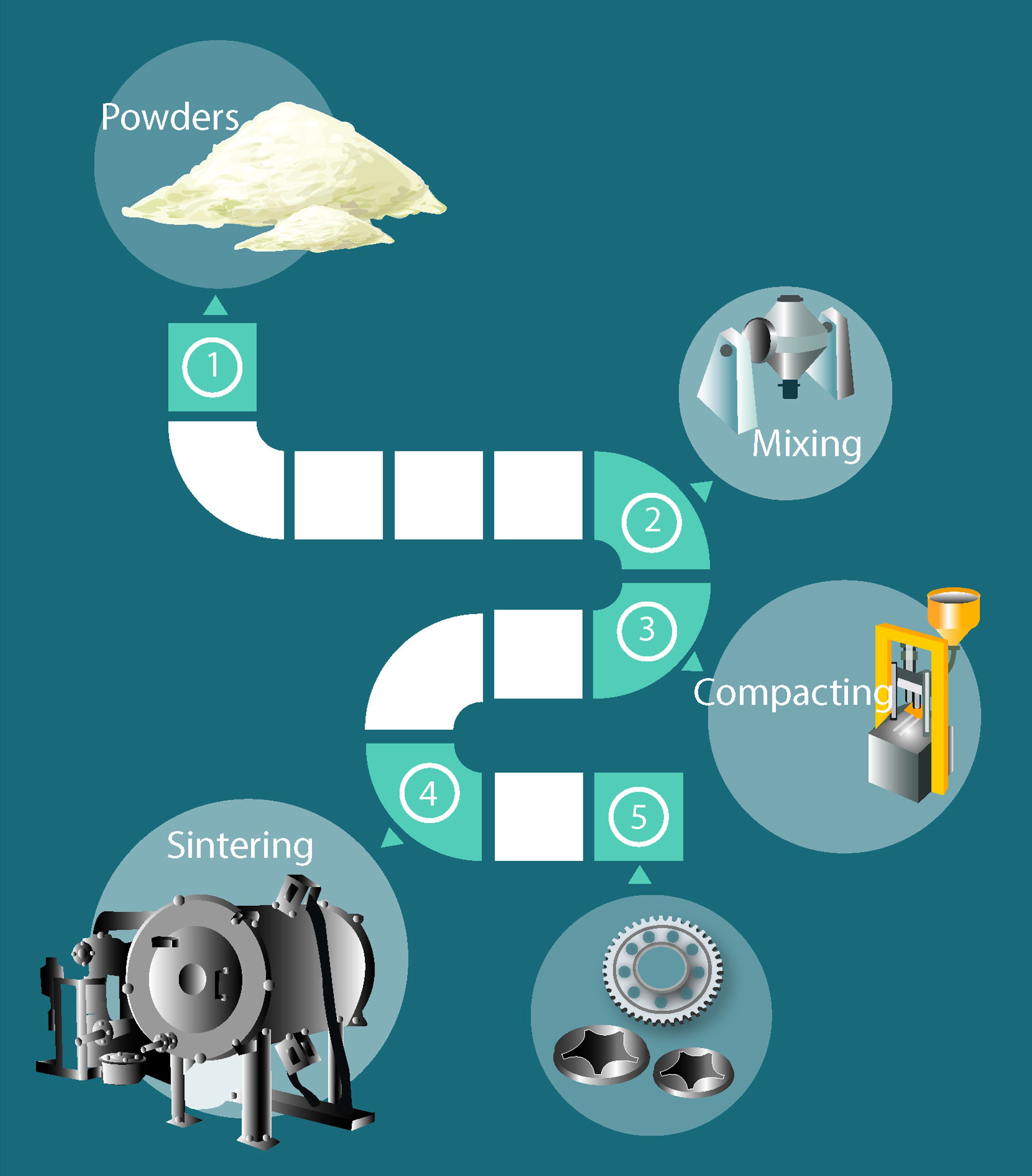

Background

Standard Unit Supply (Thailand) Co., Ltd. (SUS) would like to investigate its compaction and sintering process to improve the slightly low corrosion resistance in some of its products. Prior to working with MTEC, SUS had consulted domestic and international experts but no practical solution could be found.

Objective

To improve the sintering process to increase the corrosion resistance without compromising other properties of the sintered products. Detailed works

(1) The cause of the slightly low corrosion resistance was firstly investigated. It was found that the sintering atmosphere and the surface modification steps were not suitable.

(2) Twenty-one different combinations of processing steps were evaluated in laboratory-scale testing at MTEC to identify the optimum condition.

(3) The optimal processing steps were implemented in pilot-scale, and subsequently industrial-scale at SUS with the consultancy of MTEC team throughout the implementation.

Results

The corrosion resistance of SUS sintered products increases tenfold from the salt spray test and meets other required industrial standards e.g. mechanical load test.

Present status

SUS has commercially implemented the suggested processing steps. As a results, the production cost has been reduced and the sales have been increased. In addition, there is no waste water in the improved processing steps and this reduces the environmental concerns. It is estimated that an economic impact of approximately 140 million THB per year can be achieved.

Outlook

The research team will continue accumulating knowledge and support industries via R&D to foster innovative products related to powder metallurgy.

Opinion from the Company

Mr.Jamorn Klanpolrang, SUS Specialist in sintering, mentioned about the reasons that SUS chose to work with MTEC. “MTEC is a governmental institute that was setup to carry out R&D in materials for the sustainability development of Thailand. MTEC also has knowledgeable and experienced personals. Not only MTEC has advanced equipment, but also technical expertise. This is highly suitable for SUS, which runs a business in manufacturing metal parts. In the future, SUS is interested in developing further R&D projects with MTEC regarding aluminium, stainless steel and plastic resin.” “This project introduced SUS to use science and technology to improve its production processes as well as to create new products. Since then, SUS has conducted several process improvement projects with MTEC.”