Qualities improvement of HDPE cable spacers

Background

The Provincial Electricity Authority (PEA) has supplied electrical power in various forms. A cable spacer is one of the most important devices used with space aerial cable (SAC) for carrying the cable weight and safely putting it in order. The high density polyethylene (HDPE) cable spacer currently in used by the PEA is prone to shattered, degraded, electrical-tracked and even ignited. These negative aspects affect the service quality of PEA and the confidence in HDPE cable spacer performance, resulting in a significant amount of HDPE spacer discarded in storage facility. Therefore, the HDPE cable spacer with improved quality would contribute to a longer service time and a reduction of the operating cost of the PEA.

Goal

MTEC research team will investigate and gather information of HDPE cable spacer currently in used by PEA, design and fabricate HDPE cable spacer prototype suitable for 22 kV and 33 kV space aerial cable systems. The developed HDPE cable spacer prototype must be ultraviolet resistant and possesses flame retardant ability and mechanical strength higher than those of HDPE cable spacer currently in used by PEA. The PEA will conduct the field tests of the developed HDPE cable spacer prototype under various environmental conditions.

What does the research team do?

Design and analysis, Material selections and Process improvement

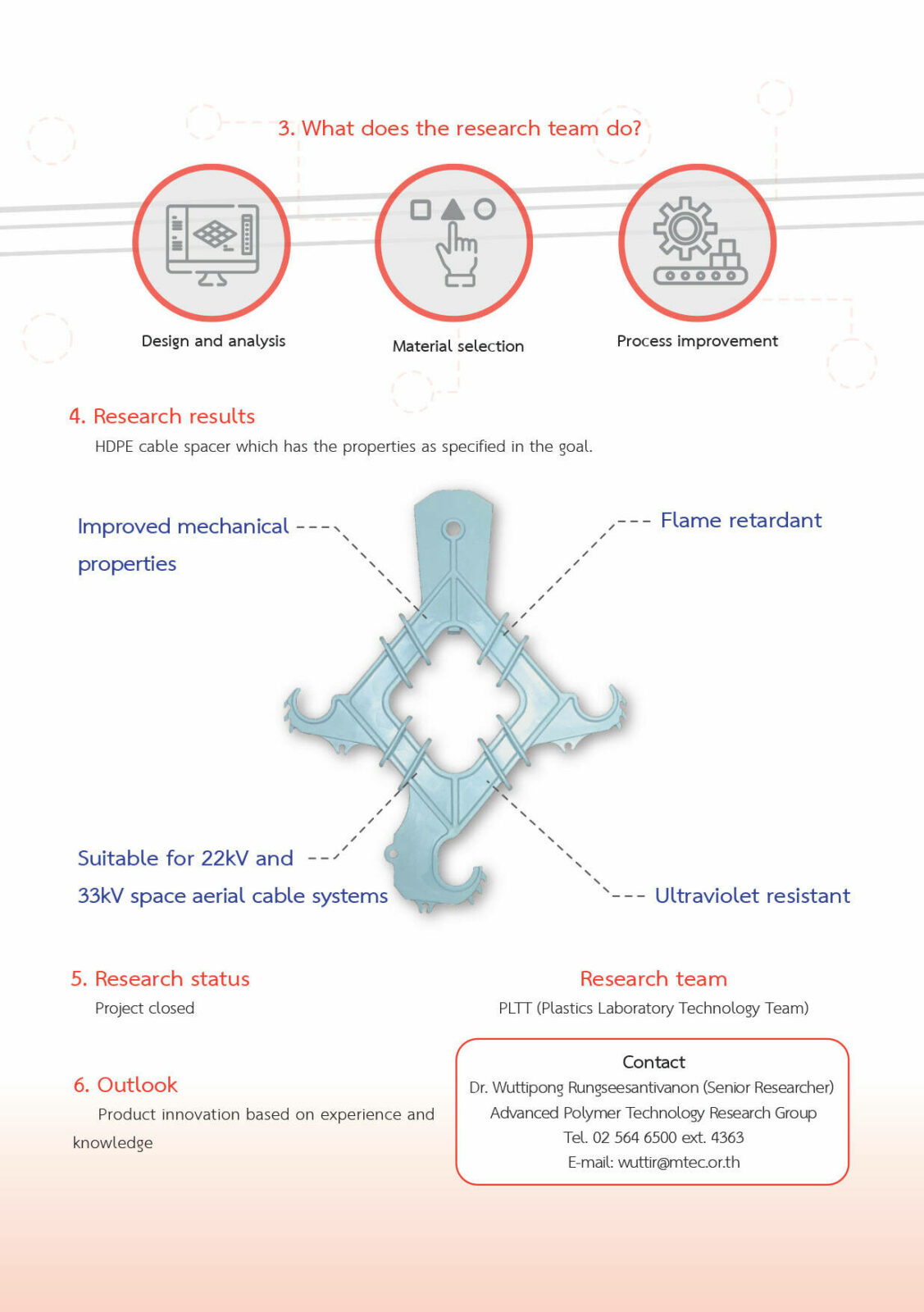

Research results

HDPE cable spacer which has the properties as specified in the goal.

Research status

Project closed

Outlook

Product innovation based on experience and knowledge

Research team:

PLTT (Plastics Laboratory Technology Team)

Contact:

Dr. Wuttipong Rungseesantivanon (Senior Researcher)

Advanced Polymer Technology Research Group

Tel. 02 564 6500 ext. 4363

E-mail: wuttir@mtec.or.th