> Prototypes for Public Usage

Thailand currently lacks emergency rescue equipment that is robust and reliable for transporting patients swiftly and safely in extreme environments and also affordable enough for widespread adoption. Such specialized rescue equipment is essential to the work of rescuers and emergency medical teams, especially those who work in extreme locations.

The National Institute for Emergency Medicine and National Metal and Materials Technology Center thus launched a collaborative research and development project to design and engineer an innovative basket stretcher that can be used in extreme rescue missions in Thailand, ranging from land to water to air rescues. The technical challenge was to develop a basket stretcher that was light, easy to transport, made of a robust material, surpassed the strength requirements of an international standard, and could support very heavy patients. The design and engineering must also take into consideration the manufacturing processes that would be practical and cost-effective for small-scale domestic producers.

The research team used the human-centric design approach to develop a new basket stretcher design, through iterations of observation, ideation, prototyping, and testing.

The observation stage involved discoveries of insights into the users and their use contexts, by interviewing the rescuers, nurses, EMS and EMT personnel, doctors, hospital staff, and governmental administrators, and observing their practices at different sites in remote mountains and sea. The needs, both functional and emotional, were distilled into a coherent problem definition and design brief.

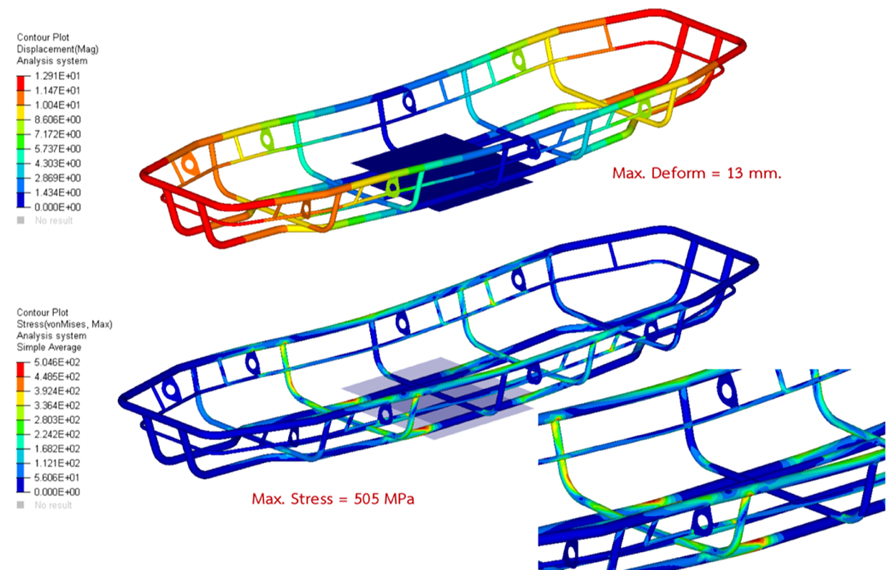

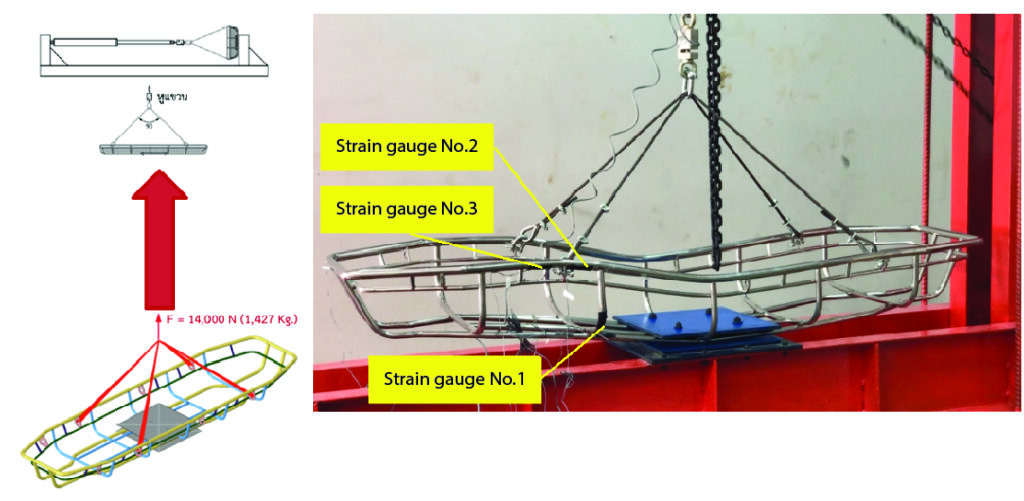

Various ideas for solutions were developed during the ideation stage. Selected designs were modeled and analyzed for its strength using finite element analyses according to the NFPA 1983 standard.

Prototypes of the designs were built and provided to the users for testing. Lab-scale and field-scale prototypes were tested in Mae Hong Son province, in collaboration with representatives from 4 rescue organizations in the nearby areas.

The results both from the computer analyses and field tests indicated that the basket stretcher fulfilled the users’ requirements, with its light weight, high strength, and suitability for extreme environments.

The designed carabiner attachment points were proven to work effectively with the rescuers’ carabiner and rope systems. Additionally, the accessorial wheel systems were found to be helpful for traversing rough terrains. The basket stretcher was designed for domestic manufacturing, taking into account the local materials, production processes, and production costs.

Prototypes for public use and engineering drawings can be made publicly available to small-scale local producers or welders so that they can produce the basket stretchers and perform basic quality assurances by themselves.

This work should lead to widespread domestic production and sustainable adoption of high-quality basket stretchers, reduce the needs for imported stretchers, and ultimately improve the emergency medical systems in Thailand.

Research team

Sarawut Lerspalungsanti and Design and Industry Solutions Research Team