> Commercial Prototype

The 16-inch electric fan blade is one of the very high-demand fan blade models produced in Hatari’s factory, with a total of eight original molds having either a sprue gate or 3 pin-point gates.

The Blade 16 produced by these molds normally have problems such as imbalance resulting from unbalanced filling of both 1-gate and 3-gate molds. It was also found that the blade 16 had different cooling rates for each blade because of the improper mold cooling system where there is only one cooling channel in the cavity side, which only cools the three impellers and one in the core side that cools the impellers together with the other 3 in the hub area. All of these molds have an average cooling time of 24.7 seconds and an average cycle time of 36 seconds, which gives rise to an average productivity of 100 blades/hour. In addition, parts reworked by labor always requires cutting either sprue gate or flashing around the blades. Moreover, as a result of insufficient cooling design of the mold, a relatively low cooling water temperature of 15-18°C was required to cool the mold, leading to brittleness of the molded parts.

MTEC research team had designed and developed an injection mold for 16-inch electric fan blades with a conformal cooling system in the hub areas, capable of effectively reducing the cooling time and increasing productivity as well as getting blades 16 that have good strength and balance. All of these have led to the reduction of the overall production cost by applying knowledge of engineering design of plastic parts and molds, especially mold cooling system design with conformal cooling together with injection molding simulation, knowledge of plastic injection molding to produce good quality parts and reduce the cycle time, as well as testing for the balance values and mechanical strength of the produced parts.

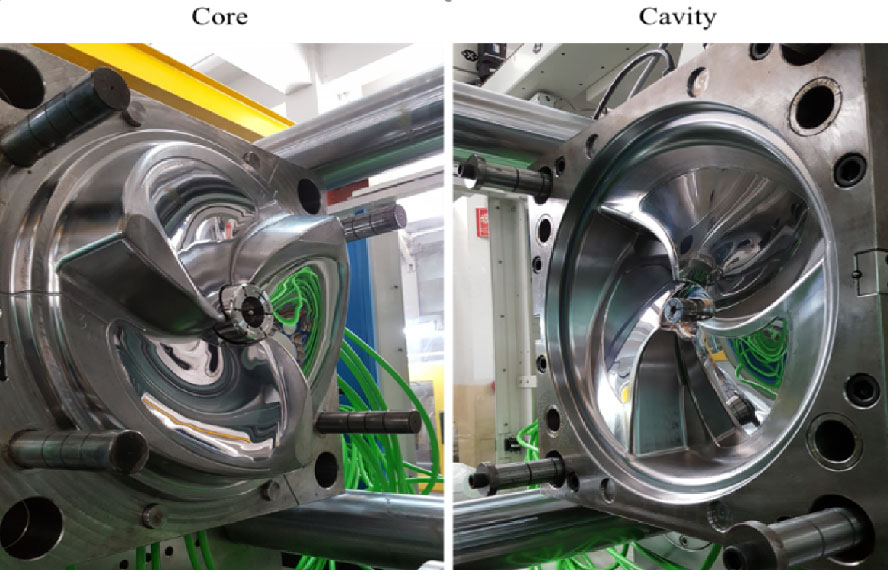

The injection mold for blade 16 developed by MTEC research team has the following characteristics:

- Injection mold having the conformal cooling system in particular cooling at the center hub, using conformal cooled core and cavity inserts built by SLM (Selective Laser Melting) process.

- Injection mold equipped with a hot runner system using 3 pin-point gate positions to ensure a uniform flow of plastic into the mold. This resulted in well-balanced blades 16 having good strength. No reworks of the part are required.

- Injection mold that can inject blade 16 parts with SAN (Styrene-acrylonitrile) material at an increased production rate of 145 pieces per hour even at a higher water temperature of 30oC compared to company’s traditional water temperature settings of 15-18oC. This represents a 45% increase in productivity compared to those of the original molds.

The developed mold has been successfully used in the mass production of blade 16 at Hatari’s factory since 2017 up until now.

The company has been using the research results as a guideline for designing various plastics parts and molds by focusing on the design of the mold cooling system to achieve maximum quality and productivity. This is the main factor that determines the cycle time and quality of those plastic parts.

Research team

Patcharee Larpsuriyakul and Plastic Product Development Research Team